Rice Science ›› 2024, Vol. 31 ›› Issue (4): 475-488.DOI: 10.1016/j.rsci.2024.02.006

• • 上一篇

收稿日期:2023-11-17

接受日期:2024-01-23

出版日期:2024-07-28

发布日期:2024-08-08

. [J]. Rice Science, 2024, 31(4): 475-488.

| Reheated convenience rice | Total solid content (mg/g) | Protein content (%) | Total starch content (%) | Amylose content (%) | Amylopectin amount (mg/g) |

|---|---|---|---|---|---|

| SHS_58% | 15.0 ± 1.9 c | 4.9 ± 0.3 b | 78.2 ± 0.3 c | 17.0 ± 0.5 b | 9.2 ± 0.0 e |

| SHS_63% | 20.2 ± 0.5 b | 5.1 ± 0.2 ab | 78.9 ± 0.4 c | 17.4 ± 0.5 ab | 12.4 ± 0.1 d |

| AEC_58% | 24.2 ± 0.9 ab | 5.3 ± 0.2 a | 80.6 ± 0.6 b | 18.4 ± 0.2 a | 15.1 ± 0.1 c |

| AEC_63% | 27.7 ± 3.7 a | 5.4 ± 0.2 a | 81.5 ± 0.2 ab | 18.6 ± 0.3 a | 17.2 ± 0.0 b |

| PSC_63% | 28.4 ± 1.1 a | 5.4 ± 0.1 a | 81.8 ± 1.4 a | 18.5 ± 0.6 a | 18.0 ± 0.3 a |

Table 1. Compositions of leachate obtained from convenience rice using different processing technologies.

| Reheated convenience rice | Total solid content (mg/g) | Protein content (%) | Total starch content (%) | Amylose content (%) | Amylopectin amount (mg/g) |

|---|---|---|---|---|---|

| SHS_58% | 15.0 ± 1.9 c | 4.9 ± 0.3 b | 78.2 ± 0.3 c | 17.0 ± 0.5 b | 9.2 ± 0.0 e |

| SHS_63% | 20.2 ± 0.5 b | 5.1 ± 0.2 ab | 78.9 ± 0.4 c | 17.4 ± 0.5 ab | 12.4 ± 0.1 d |

| AEC_58% | 24.2 ± 0.9 ab | 5.3 ± 0.2 a | 80.6 ± 0.6 b | 18.4 ± 0.2 a | 15.1 ± 0.1 c |

| AEC_63% | 27.7 ± 3.7 a | 5.4 ± 0.2 a | 81.5 ± 0.2 ab | 18.6 ± 0.3 a | 17.2 ± 0.0 b |

| PSC_63% | 28.4 ± 1.1 a | 5.4 ± 0.1 a | 81.8 ± 1.4 a | 18.5 ± 0.6 a | 18.0 ± 0.3 a |

| Reheated convenience rice | Average chain length (DP) | Amylopectin chain length distribution (%) | |||

|---|---|---|---|---|---|

| DP 6‒12 (A chain) | DP 13‒24 (B1 chain) | DP 25‒36 (B2 chain) | DP ≥ 37 (B3+ chain) | ||

| SHS_58% | 19.3 ± 0.0 b | 30.3 ± 0.0 b | 48.8 ± 0.3 a | 11.0 ± 0.0 a | 9.9 ± 0.3 b |

| SHS_63% | 19.4 ± 0.1 ab | 30.4 ± 0.2 b | 48.4 ± 0.1 b | 11.0 ± 0.0 a | 10.3 ± 0.1 ab |

| AEC_58% | 19.4 ± 0.0 ab | 30.3 ± 0.2 b | 48.2 ± 0.1 b | 11.1 ± 0.1 a | 10.4 ± 0.1 a |

| AEC_63% | 19.4 ± 0.0 ab | 30.5 ± 0.2 ab | 48.2 ± 0.1 b | 11.0 ± 0.0 a | 10.3 ± 0.1 ab |

| PSC_63% | 19.5 ± 0.1 a | 30.8 ± 0.4 a | 48.5 ± 0.3 ab | 10.4 ± 0.3 b | 10.4 ± 0.3 a |

Table 2. Amylopectin branch chain length distribution of leachate obtained from convenience rice using different processing technologies.

| Reheated convenience rice | Average chain length (DP) | Amylopectin chain length distribution (%) | |||

|---|---|---|---|---|---|

| DP 6‒12 (A chain) | DP 13‒24 (B1 chain) | DP 25‒36 (B2 chain) | DP ≥ 37 (B3+ chain) | ||

| SHS_58% | 19.3 ± 0.0 b | 30.3 ± 0.0 b | 48.8 ± 0.3 a | 11.0 ± 0.0 a | 9.9 ± 0.3 b |

| SHS_63% | 19.4 ± 0.1 ab | 30.4 ± 0.2 b | 48.4 ± 0.1 b | 11.0 ± 0.0 a | 10.3 ± 0.1 ab |

| AEC_58% | 19.4 ± 0.0 ab | 30.3 ± 0.2 b | 48.2 ± 0.1 b | 11.1 ± 0.1 a | 10.4 ± 0.1 a |

| AEC_63% | 19.4 ± 0.0 ab | 30.5 ± 0.2 ab | 48.2 ± 0.1 b | 11.0 ± 0.0 a | 10.3 ± 0.1 ab |

| PSC_63% | 19.5 ± 0.1 a | 30.8 ± 0.4 a | 48.5 ± 0.3 ab | 10.4 ± 0.3 b | 10.4 ± 0.3 a |

| Reheated convenience rice | Hardness (g) | Adhesiveness (g∙s) | Springiness | Cohesiveness | Chewiness (g) |

|---|---|---|---|---|---|

| SHS_58% | 2 705.0 ± 10.1 c | 9.3 ± 0.5 e | 0.819 ± 0.015 b | 0.624 ± 0.011 b | 1 272.6 ± 15.2 c |

| SHS_63% | 2 546.5 ± 37.0 d | 10.5 ± 0.6 d | 0.832 ± 0.022 b | 0.624 ± 0.008 b | 1 178.8 ± 22.0 d |

| AEC_58% | 3 242.2 ± 13.3 a | 13.0 ± 0.5 c | 0.874 ± 0.008 a | 0.659 ± 0.005 a | 1 768.1 ± 25.6 a |

| AEC_63% | 2 160.0 ± 19.3 e | 16.9 ± 0.7 b | 0.837 ± 0.031 b | 0.613 ± 0.012 b | 1 103.9 ± 9.0 e |

| PSC_63% | 2 817.6 ± 39.3 b | 19.5 ± 0.4 a | 0.767 ± 0.028 c | 0.598 ± 0.009 c | 1 438.1 ± 38.7 b |

Table 3. Textural properties of convenience rice using different processing technologies.

| Reheated convenience rice | Hardness (g) | Adhesiveness (g∙s) | Springiness | Cohesiveness | Chewiness (g) |

|---|---|---|---|---|---|

| SHS_58% | 2 705.0 ± 10.1 c | 9.3 ± 0.5 e | 0.819 ± 0.015 b | 0.624 ± 0.011 b | 1 272.6 ± 15.2 c |

| SHS_63% | 2 546.5 ± 37.0 d | 10.5 ± 0.6 d | 0.832 ± 0.022 b | 0.624 ± 0.008 b | 1 178.8 ± 22.0 d |

| AEC_58% | 3 242.2 ± 13.3 a | 13.0 ± 0.5 c | 0.874 ± 0.008 a | 0.659 ± 0.005 a | 1 768.1 ± 25.6 a |

| AEC_63% | 2 160.0 ± 19.3 e | 16.9 ± 0.7 b | 0.837 ± 0.031 b | 0.613 ± 0.012 b | 1 103.9 ± 9.0 e |

| PSC_63% | 2 817.6 ± 39.3 b | 19.5 ± 0.4 a | 0.767 ± 0.028 c | 0.598 ± 0.009 c | 1 438.1 ± 38.7 b |

| Reheated convenience rice | Glossiness | Whiteness | Roasted flavor | Hardness | Stickiness | Moistness | Overall acceptability |

|---|---|---|---|---|---|---|---|

| SHS_58% | 4.6 ± 0.5 d | 6.8 ± 0.4 a | 4.7 ± 0.5 b | 6.3 ± 0.5 b | 3.4 ± 0.5 c | 3.1 ± 0.3 d | 5.3 ± 0.5 b |

| SHS_63% | 5.3 ± 0.5 c | 6.6 ± 0.5 a | 4.4 ± 0.5 b | 5.6 ± 0.5 c | 5.3 ± 0.5 b | 4.6 ± 0.5 c | 4.4 ± 0.5 c |

| AEC_58% | 5.4 ± 0.5 c | 5.6 ± 0.5 b | 6.6 ± 0.5 a | 7.8 ± 0.9 a | 5.7 ± 0.9 b | 4.8 ± 0.4 c | 5.9 ± 0.4 b |

| AEC_63% | 6.5 ± 0.5 b | 5.3 ± 0.5 b | 6.5 ± 0.5 a | 5.5 ± 0.6 c | 6.5 ± 0.5 a | 5.5 ± 0.5 b | 5.5 ± 0.5 b |

| PSC_63% | 8.5 ± 0.5 a | 4.3 ± 0.9 c | 4.3 ± 0.5 b | 6.9 ± 0.9 b | 5.4 ± 0.5 b | 6.7 ± 0.8 a | 6.8 ± 0.9 a |

Table 4. Sensory characteristics of reheated convenience rice using different processing technologies..

| Reheated convenience rice | Glossiness | Whiteness | Roasted flavor | Hardness | Stickiness | Moistness | Overall acceptability |

|---|---|---|---|---|---|---|---|

| SHS_58% | 4.6 ± 0.5 d | 6.8 ± 0.4 a | 4.7 ± 0.5 b | 6.3 ± 0.5 b | 3.4 ± 0.5 c | 3.1 ± 0.3 d | 5.3 ± 0.5 b |

| SHS_63% | 5.3 ± 0.5 c | 6.6 ± 0.5 a | 4.4 ± 0.5 b | 5.6 ± 0.5 c | 5.3 ± 0.5 b | 4.6 ± 0.5 c | 4.4 ± 0.5 c |

| AEC_58% | 5.4 ± 0.5 c | 5.6 ± 0.5 b | 6.6 ± 0.5 a | 7.8 ± 0.9 a | 5.7 ± 0.9 b | 4.8 ± 0.4 c | 5.9 ± 0.4 b |

| AEC_63% | 6.5 ± 0.5 b | 5.3 ± 0.5 b | 6.5 ± 0.5 a | 5.5 ± 0.6 c | 6.5 ± 0.5 a | 5.5 ± 0.5 b | 5.5 ± 0.5 b |

| PSC_63% | 8.5 ± 0.5 a | 4.3 ± 0.9 c | 4.3 ± 0.5 b | 6.9 ± 0.9 b | 5.4 ± 0.5 b | 6.7 ± 0.8 a | 6.8 ± 0.9 a |

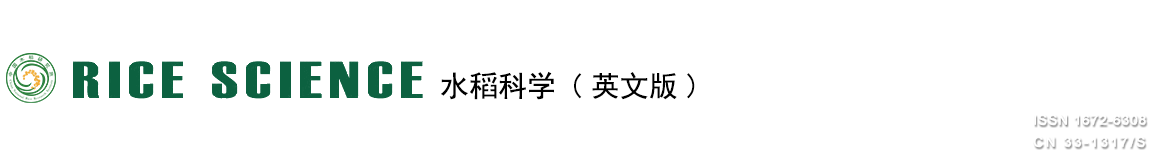

Fig. 1. Scanning electron microscopy images of outer (A1‒E1) and inner (A2‒E2) cross-section, and surface (A3‒E3) of reheated convenience rice using different processing technologies (500× magnification). A1‒A3, Super-heated steaming with 58% water content (SHS_58%); B1‒B3, Super-heated steaming with 63% water content (SHS_63%); C1‒C3, Auto-electric cooking with 58% water content (AEC_58%); D1‒D3, Auto-electric cooking with 63% water content (AEC_63%); E1‒E3, Pressurized-steam cooking with 63% water content (PSC_63%). The red arrows in E2 indicate longitudinal chunks, and white lines in A1‒E1 represent the thickness of coated layer.

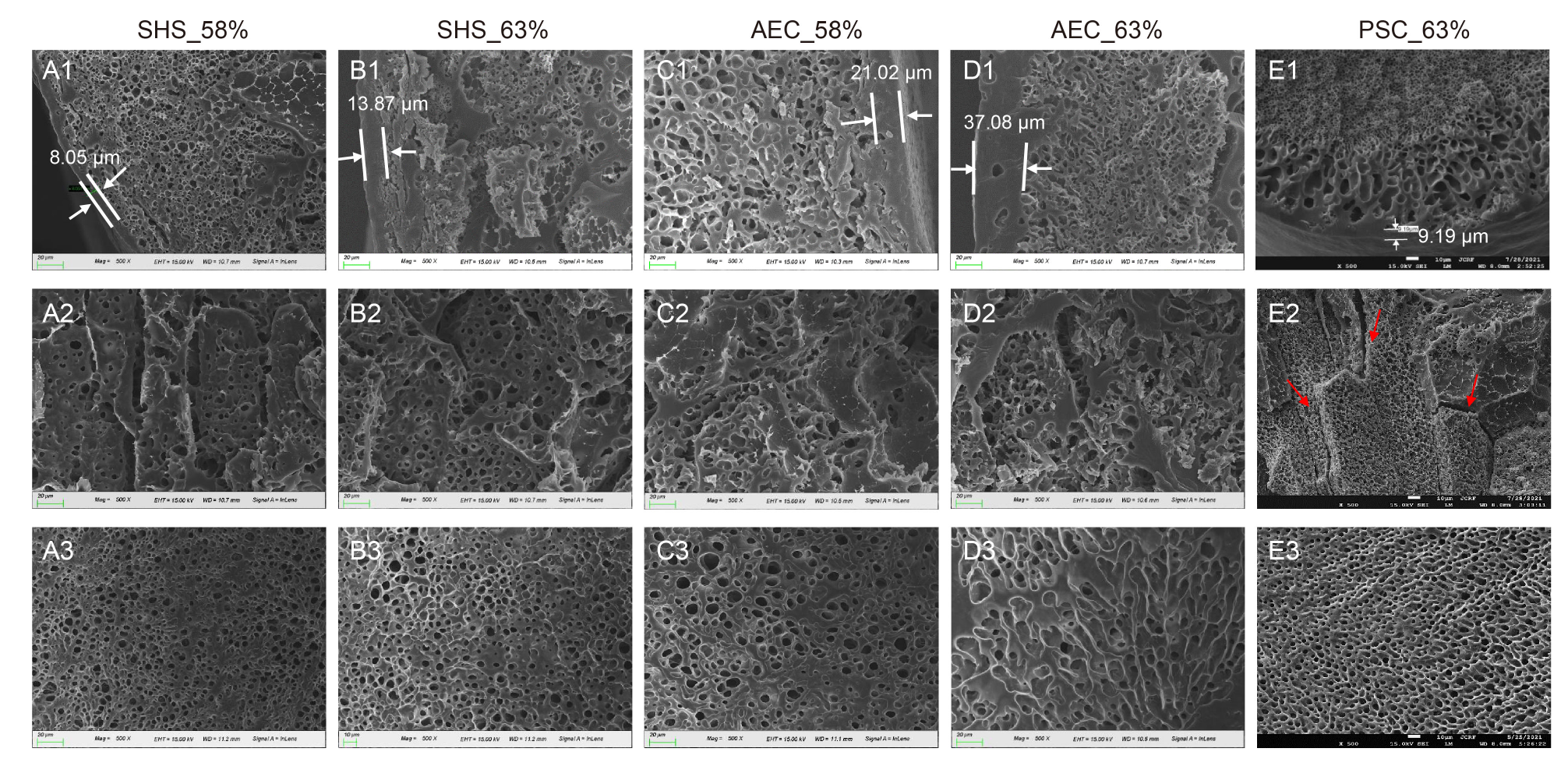

Fig. 2. Confocal laser scanning microscopy images of outer (A1‒E1) and inner (A2‒E2) regions of reheated convenience rice using different processing technologies (200× magnification). A1 and A2, Super-heated steaming with 58% water content (SHS_58%); B1 and B2, Super-heated steaming with 63% water content (SHS_63%); C1 and C2, Auto-electric cooking with 58% water content (AEC_58%); D1 and D2, Auto-electric cooking with 63% water content (AEC_63%); E1 and E2, Pressurized-steam cooking with 63% water content (PSC_63%). The green and red colors in images indicate starch and protein in the reheated convenience rice, respectively. White arrows in A1, A2, B1, and B2 indicate polygonal starch granules.

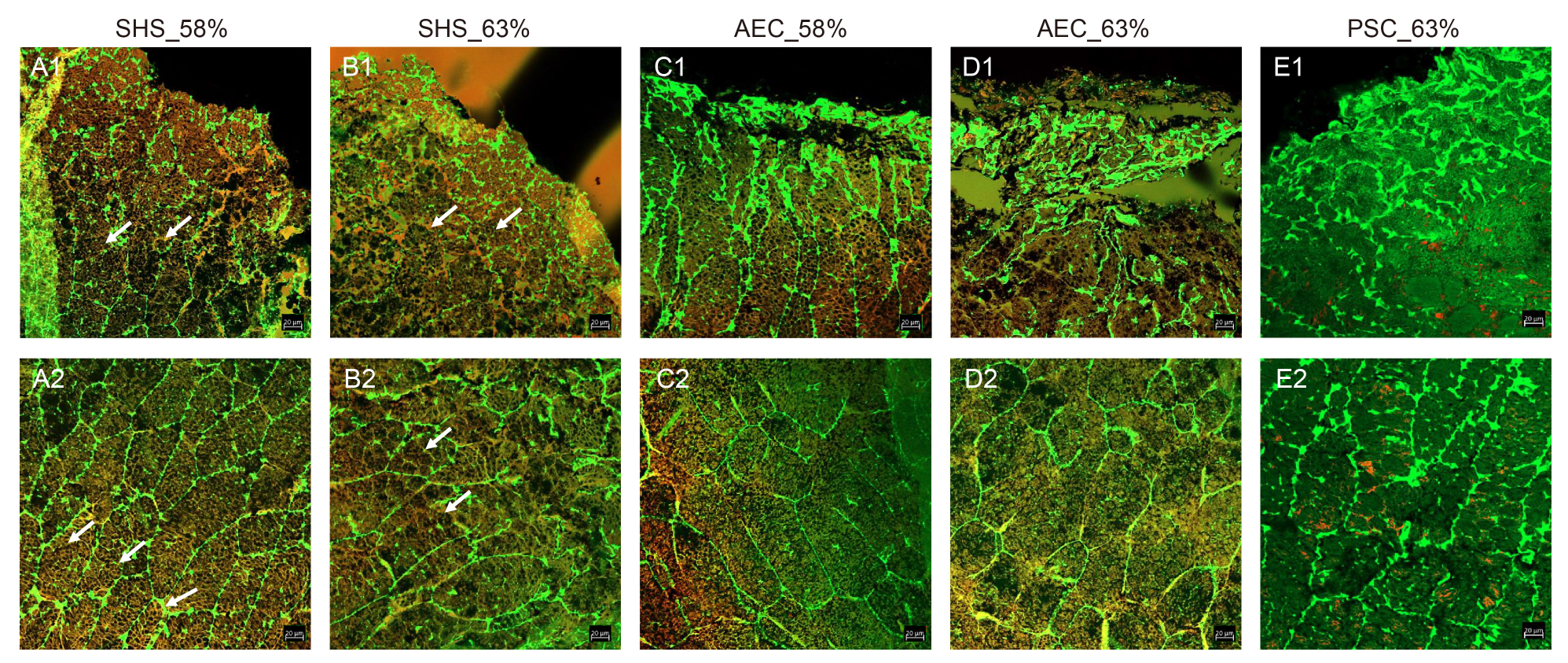

Fig. 3. Score (A) and loading (B) plots for principal component analysis (PCA) derived from leachate compositions and textural and sensory characteristics of reheated convenience rice using different processing technologies. SHS, Super-heated steaming; AEC, Auto-electric cooking; PSC, Pressurized-steam cooking; TA, Texture analysis; SE, Sensory evaluation; ACL, Average chain length; DP, Degree of polymerization. 58% and 63% are two target water contents.

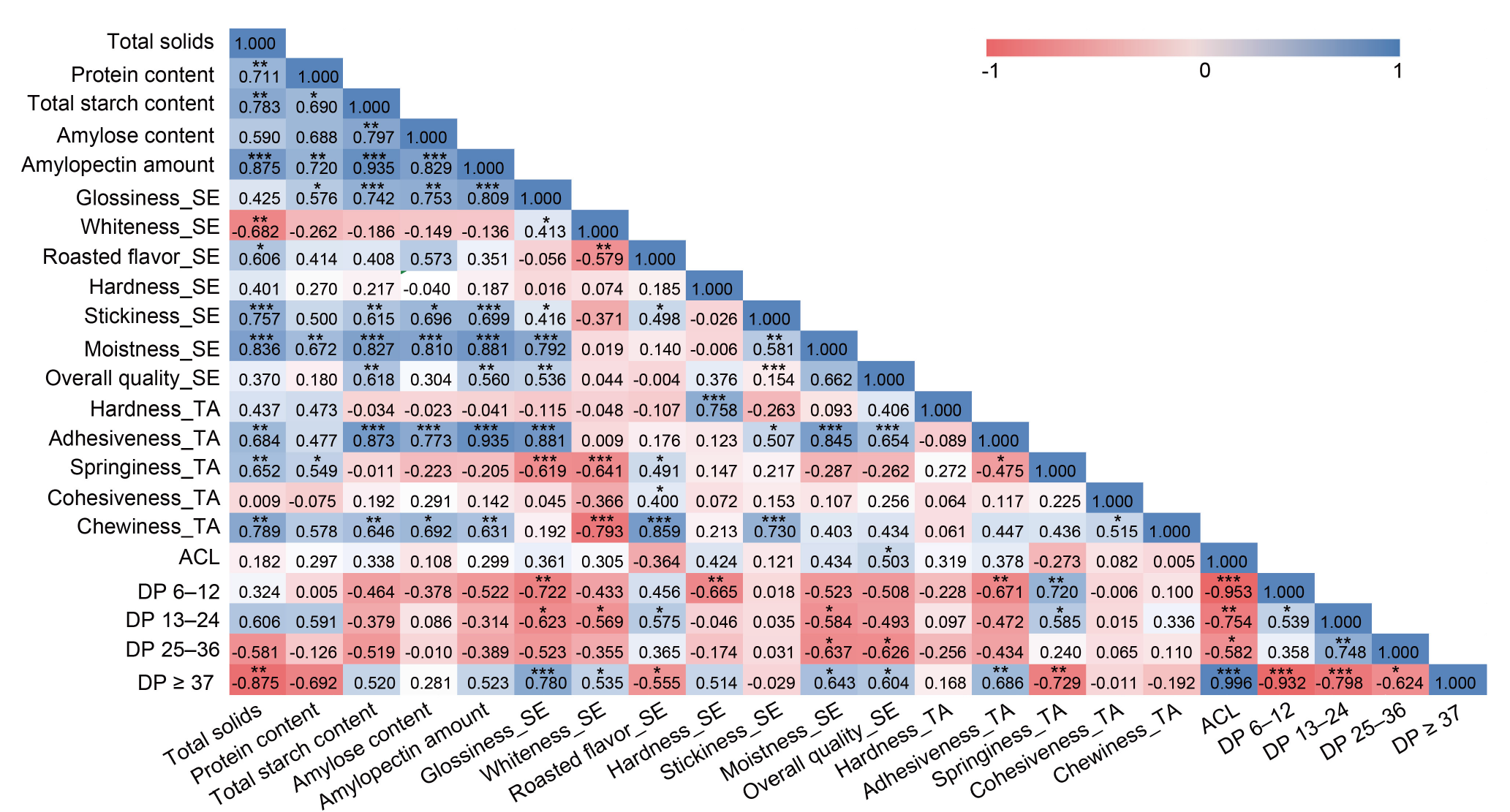

Fig. 4. Pearson correlation coefficients for relationship between compositions of leachate, texture properties, and sensory characteristics of reheated convenience rice using different processing technologies. TA, Texture analysis; SE, Sensory evaluation; ACL, Average chain length; DP, Degree of polymerization. *, **, and *** mean that the correlations are significant at P ≤ 0.05, P ≤ 0.01, and P ≤ 0.001, respectively.

| [1] | Bett-Garber K L, Champagne E T, Ingram D A, McClung A M. 2007. Influence of water-to-rice ratio on cooked rice flavor and texture. Cereal Chem, 84(6): 614-619. |

| [2] | Bi J C, Yang Z, Li Y, Li B, Gao Y Y, Ping C Y, Chen Z, Li C F. 2023. Effects of different cooking methods on volatile flavor compounds in garlic. Int J Gastron Food Sci, 31: 100642. |

| [3] | Briffaz A, Mestres C, Escoute J, Lartaud M, Dornier M. 2012. Starch gelatinization distribution and peripheral cell disruption in cooking rice grains monitored by microscopy. J Cereal Sci, 56(3): 699-705. |

| [4] | Brown L G, McEnally M R. 1992. Convenience: Definition, structure, and application. J Mark Manag, 2: 47-56. |

| [5] | Bui L T T, Coad R A, Stanley R A. 2018. Properties of rehydrated freeze dried rice as a function of processing treatments. LWT, 91: 143-150. |

| [6] | Champagne E T, Bett-Garber K L, Fitzgerald M A, Grimm C C, Lea J, Ohtsubo K, Jongdee S, Xie L H, Bassinello P Z, Resurreccion A, Ahmad R, Habibi F, Reinke R. 2010. Important sensory properties differentiating premium rice varieties. Rice, 3(4): 270-281. |

| [7] | Chen X, Zhang X X, Wang B Y, Chen P R, Xu Y, Du X F. 2019. Investigation of water migration and its impacts on eating qualities of black rice during cooking process. J Cereal Sci, 89: 102810. |

| [8] | Choi I D, Oh Y G, Kwak J E, Chun A, Kim M J, Hyun W J. 2021. Water-absorption characteristics and cooked rice texture of milled rice. Korean J Food Sci Technol, 53(4): 486-494. |

| [9] | Chusak C, Ying J A Y, Zhien J L, Pasukamonset P, Henry C J, Ngamukote S, Adisakwattana S. 2019. Impact of Clitoria ternatea (butterfly pea) flower on in vitro starch digestibility, texture and sensory attributes of cooked rice using domestic cooking methods. Food Chem, 295: 646-652. |

| [10] | Concepcion J C T, Ouk M, Zhao D L, Fitzgerald M A. 2015. The need for new tools and investment to improve the accuracy of selecting for grain quality in rice. Field Crops Res, 182: 60-67. |

| [11] | Crowhurst D G, Creed P G. 2001. Effect of cooking method and variety on the sensory quality of rice. Food Serv Technol, 1(3): 133-140. |

| [12] | Cui T Q, Wu Y, Ni C L, Sun Y X, Cheng J J. 2022. Rheology and texture analysis of gelatin/dialdehyde starch hydrogel carriers for curcumin controlled release. Carbohydr Polym, 283: 119154. |

| [13] | de Boer M, McCarthy M, Cowan C, Ryan I. 2004. The influence of lifestyle characteristics and beliefs about convenience food on the demand for convenience foods in the Irish market. Food Qual Prefer, 15(2): 155-165. |

| [14] | Deng F, Yang F, Li Q P, Zeng Y L, Li B, Zhong X Y, Lu H, Wang L, Chen H, Chen Y, Ren W J. 2021. Differences in starch structural and physicochemical properties and texture characteristics of cooked rice between the main crop and ratoon rice. Food Hydrocoll, 116: 106643. |

| [15] | Ha M, Jeong H Y, Lim S T, Chung H J. 2022. The cooking method features controlling eating quality of cooked rice: An explanation from the view of starch structure in leachate and morphological characteristics. Food Res Int, 162: 111980. |

| [16] | Hanashiro I, Abe J I, Hizukuri S. 1996. A periodic distribution of the chain length of amylopectin as revealed by high-performance anion-exchange chromatography. Carbohydr Res, 283: 151-159. |

| [17] | Huang M, Kennedy J F, Li B, Xu X, Xie B J. 2007. Characters of rice starch gel modified by gellan, carrageenan, and glucomannan: A texture profile analysis study. Carbohydr Polym, 69(3): 411-418. |

| [18] | Kim D H, Kim H S. 2007. Effects of pressure cooker brand awareness on the consumer acceptability of reheated convenience rice. J Korean Soc Food Cult, 1(1): 34-39. |

| [19] | Kim H R, Kwon Y H, Kim J H, Ahn B H. 2011. Quality analysis of diverse rice species for rice products. Korean J Food Sci Technol, 43(2): 142-148. |

| [20] | Li C, Li E P, Gong B. 2022. Main starch molecular structures controlling the textural attributes of cooked instant rice. Food Hydrocoll, 132: 107866. |

| [21] | Li H Y, Prakash S, Nicholson T M, Fitzgerald M A, Gilbert R G. 2016a. The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem, 196: 702-711. |

| [22] | Li H Y, Prakash S, Nicholson T M, Fitzgerald M A, Gilbert R G. 2016b. Instrumental measurement of cooked rice texture by dynamic rheological testing and its relation to the fine structure of rice starch. Carbohydr Polym, 146: 253-263. |

| [23] | Li H Y, Wen Y Y, Wang J, Sun B G. 2017. The molecular structures of leached starch during rice cooking are controlled by thermodynamic effects, rather than kinetic effects. Food Hydrocoll, 73: 295-299. |

| [24] | Li H Y, Gilbert R G. 2018. Starch molecular structure: The basis for an improved understanding of cooked rice texture. Carbohydr Polym, 195: 9-17. |

| [25] | Li H Y, Lei N Y, Yan S, Gao M Y, Yang J Y, Wang J, Sun B G. 2019a. Molecular causes for the effect of cooking methods on rice stickiness: A mechanism explanation from the view of starch leaching. Int J Biol Macromol, 128: 49-53. |

| [26] | Li H Y, Yu L, Yu W W, Li H T, Gilbert R. 2019b. Autoclaved rice: The textural property and its relation to starch leaching and the molecular structure of leached starch. Food Chem, 283: 199-205. |

| [27] | Lin L S, Guo D W, Huang J, Zhang X D, Zhang L, Wei C X. 2016. Molecular structure and enzymatic hydrolysis properties of starches from high-amylose maize inbred lines and their hybrids. Food Hydrocoll, 58: 246-254. |

| [28] | Mar N N, Umemoto T, Ismail M, Abdullah S N A, Maziah M. 2013. Determination of amylopectin structure and physicochemical properties in rice endosperm starch of mutant lines derived from Malaysian rice cultivar MR219. J Sci Food Agric, 93(1): 110-117. |

| [29] | Meng L, Zhang W C, Wu Z Y, Hui A L, Gao H, Chen P P, He Y W. 2018. Effect of pressure-soaking treatments on texture and retrogradation properties of black rice. LWT, 93: 485-490. |

| [30] | Mestres C, Briffaz A, Valentin D. 2019. Rice cooking and sensory quality. In: Bao J S. Rice: Chemistry and Technology. 4th edn. Devon, UK: AACC International Press: 385-426. |

| [31] | Mohapatra D, Bal S. 2006. Cooking quality and instrumental textural attributes of cooked rice for different milling fractions. J Food Eng, 73(3): 253-259. |

| [32] | Ogawa Y, Glenn G M, Orts W J, Wood D F. 2003. Histological structures of reheated convenience rice grain. J Agric Food Chem, 51: 7019-7023. |

| [33] | Okuda R, Ishimura T, Kanatani A. 2009. Study on rice cooking: Part 1. Effect of solid components in the rice cooking liquid on the rice grain surface. J Cookery Sci Jpn, 42(6): 394-403. |

| [34] | Park H Y, Shin D S, Woo K S, Sim E Y, Kim H J, Lee S K, Won Y J, Lee S B, Oh S K. 2016. Mechanical quality evaluation of rice cultivars that could potentially be used to produce processed cooked rice. Korean J Crop Sci, 61: 145-152. |

| [35] | Park S G, Park H S, Baek M K, Jeong J M, Cho Y C, Lee G M, Lee C M, Suh J P, Kim C S, Kim S M. 2019. Improving the glossiness of cooked rice, an important component of visual rice grain quality. Rice, 12(1): 87. |

| [36] | Patindol J, Gu X F, Wang Y J. 2010. Chemometric analysis of cooked rice texture in relation to starch fine structure and leaching characteristics. Starch-Starke, 62(3/4): 188-197. |

| [37] | Pematilleke N, Kaur M, Adhikari B, Torley P J. 2022. Relationship between instrumental and sensory texture profile of beef semitendinosus muscles with different textures. J Texture Stud, 53(2): 232-241. |

| [38] | Prasert W, Suwannaporn P. 2009. Optimization of instant jasmine rice process and its physicochemical properties. J Food Eng, 95(1): 54-61. |

| [39] | Rewthong O, Soponronnarit S, Taechapairoj C, Tungtrakul P, Prachayawarakorn S. 2011. Effects of cooking, drying and pretreatment methods on texture and starch digestibility of instant rice. J Food Eng, 103(3): 258-264. |

| [40] | Scholliers P. 2015. Convenience foods. what, why, and when. Appetite, 94: 2-6. |

| [41] | Son J S, Do V B, Kim K O, Cho M S, Suwonsichon T, Valentin D. 2013. Consumers’ attitude towards rice cooking processes in Korea, Japan, Thailand and France. Food Qual Prefer, 29(1): 65-75. |

| [42] | Srisawas W, Jindal V K. 2007. Sensory evaluation of cooked rice in relation to water-to-rice ratio and physicochemical properties. J Texture Stud, 38(1): 21-41. |

| [43] | Tamura M, Ogawa Y. 2012. Visualization of the coated layer at the surface of rice grain cooked with varying amounts of cooking water. J Cereal Sci, 56(2): 404-409. |

| [44] | Tamura M, Nagai T, Hidaka Y, Noda T, Yokoe M, Ogawa Y. 2014. Changes in histological tissue structure and textural characteristics of rice grain during cooking process. Food Struct, 1(2): 164-170. |

| [45] | Tao K Y, Yu W W, Prakash S, Gilbert R G. 2019. High-amylose rice: Starch molecular structural features controlling cooked rice texture and preference. Carbohydr Polym, 219: 251-260. |

| [46] | Tao K Y, Yu W W, Prakash S, Gilbert R G. 2020. Investigating cooked rice textural properties by instrumental measurements. Food Sci Hum Wellness, 9(2): 130-135. |

| [47] | Tian Y Q, Zhao J W, Xie Z J, Wang J P, Xu X M, Jin Z Y. 2014. Effect of different pressure-soaking treatments on color, texture, morphology and retrogradation properties of cooked rice. LWT- Food Sci Technol, 55(1): 368-373. |

| [48] | Williams P C, Kuzina F D, Hlynka I. 1970. A rapid colorimetric procedure for estimating the amylose content of starches and flours. Cereal Chem, 47: 411-420. |

| [49] | Wong K S, Jane J. 1995. Effects of pushing agents on the separation and detection of debranched amylopectin by high-performance anion-exchange chromatography with pulsed amperometric detection. J Liq Chromatogr, 18(1): 63-80. |

| [50] | Xu D P, Hong Y, Gu Z B, Cheng L, Li Z F, Li C M. 2019. Effect of high-pressure steam on the eating quality of reheated convenience rice. LWT-Food Sci Technol, 104: 100-108. |

| [51] | Xu D P, Hong Y, Gu Z B, Li Z F, Cheng L, Li C M. 2020. Effect of increased pressure on the coated layer profile of steamed rice. Food Chem, 310: 125971. |

| [52] | Yu L, Turner M S, Fitzgerald M, Stokes J R, Witt T. 2017. Review of the effects of different processing technologies on cooked and convenience rice quality. Trends Food Sci Technol, 59: 124-138. |

| [53] | Yu Y, Pan F, Ramaswamy H S, Zhu S M, Yu L, Zhang Q T. 2017. Effect of soaking and single/two cycle high pressure treatment on water absorption, color, morphology and cooked texture of brown rice. J Food Sci Technol, 54(6): 1655-1664. |

| [54] | Zhang Y, Li F, Huang K, Li S, Cao H W, Xie J, Guan X. 2023. Structural changes of starch under different milling degrees affect the cooking and textural properties of rice. Food Chem X, 17: 100627. |

| [55] | Zhong Y Y, Liu L S, Qu J Z, Blennow A, Hansen A R, Wu Y X, Guo D W, Liu X X. 2020. Amylose content and specific fine structures affect lamellar structure and digestibility of maize starches. Food Hydrocoll, 108: 105994. |

| [56] | Zhu L, Cheng L L, Zhang H, Wang L, Qian H F, Qi X G, Wu G C. 2019. Research on migration path and structuring role of water in rice grain during soaking. Food Hydrocoll, 92: 41-50. |

| [57] | Zhu L, Bi S L, Wu G C, Gong B, Zhang H, Wang L, Qian H F, Qi X G. 2020a. Study of the migration and molecular structure of starch and protein in rice kernel during heating. Int J Biol Macromol, 147: 1116-1124. |

| [58] | Zhu L, Wu G C, Cheng L L, Zhang H, Wang L, Qian H F, Qi X G. 2020b. Investigation on molecular and morphology changes of protein and starch in rice kernel during cooking. Food Chem, 316: 126262. |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||