Rice Science ›› 2022, Vol. 29 ›› Issue (6): 577-588.DOI: 10.1016/j.rsci.2022.03.002

• Research Paper • Previous Articles

Wang Cuili#, Guo Wen#, Hu Peisong, Wei Xiangjin, Tang Shaoqing( ), Jiao Guiai(

), Jiao Guiai( )

)

Received:2021-12-10

Accepted:2022-03-02

Online:2022-11-28

Published:2022-09-09

Contact:

Tang Shaoqing, Jiao Guiai

About author:#These authors contributed equally to this work

Wang Cuili, Guo Wen, Hu Peisong, Wei Xiangjin, Tang Shaoqing, Jiao Guiai. Differences of Physicochemical Properties Between Chalky and Translucent Parts of Rice Grains[J]. Rice Science, 2022, 29(6): 577-588.

Add to citation manager EndNote|Ris|BibTeX

| Variety | Subspecies | Chalky rice rate (%) | Chalkiness degree (%) | Type | Total starch content (%) | Amylose content (%) | Protein content (%) | Fat content (%) |

|---|---|---|---|---|---|---|---|---|

| Zhongjiazao 17 | indica | 95.0 ± 4.4 a | 20.3 ± 0.7 b | T | 85.2 ± 0.2 bc | 27.7 ± 0.4 a | 8.3 ± 0.1 c | 0.3 ± 0.0 cd |

| C | 85.7 ± 0.3 ab | 25.8 ± 0.1 c | 6.6 ± 0.0 g | 0.4 ± 0.1 c | ||||

| Zhongzao 39 | indica | 98.3 ± 0.6 a | 22.4 ± 0.5 a | T | 82.6 ± 0.4 ef | 25.4 ± 0.2 c | 9.7 ± 0.3 a | 0.6 ± 0.0 b |

| C | 81.5 ± 1.1 f | 23.4 ± 0.1 e | 8.0 ± 0.0 d | 1.1 ± 0.1 a | ||||

| Zaojian 177 | indica | 83.3 ± 1.5 b | 18.2 ± 0.6 c | T | 85.8 ± 0.9 ab | 26.3 ± 0.1 b | 9.7 ± 0.2 a | 0.3 ± 0.0 cd |

| C | 85.5 ± 0.5 ab | 24.8 ± 0.4 d | 7.4 ± 0.1 e | 0.4 ± 0.0 c | ||||

| Zhonghua 11 | japonica | 14.7 ± 2.5 d | 7.9 ± 0.8 d | T | 85.9 ± 0.6 ab | 17.3 ± 0.2 f | 9.5 ± 0.1 b | 0.3 ± 0.0 d |

| C | 86.7 ± 0.8 a | 15.7 ± 0.1 g | 6.9 ± 0.0 f | 0.7 ± 0.0 b | ||||

| Nangeng 46 | japonica | 20.0 ± 2.0 c | 5.0 ± 0.2 e | T | 84.1 ± 0.5 cd | 12.6 ± 0.4 i | 8.3 ± 0.1 c | 0.2 ± 0.1 d |

| C | 83.0 ± 0.6 de | 10.3 ± 0.3 j | 7.1 ± 0.2 f | 0.3 ± 0.0 cd | ||||

| Qiutianxiaoding | japonica | 7.0 ± 1.0 e | 0.9 ± 0.1 f | T | 85.6 ± 0.6 ab | 15.7 ± 0.3 g | 8.4 ± 0.1 c | 0.4 ± 0.0 c |

| C | 86.2 ± 0.8 ab | 13.9 ± 0.2 h | 6.3 ± 0.1 h | 0.6 ± 0.0 b |

Table 1. Physicochemical properties of translucent (T) and chalky (C) flour from six rice varieties.

| Variety | Subspecies | Chalky rice rate (%) | Chalkiness degree (%) | Type | Total starch content (%) | Amylose content (%) | Protein content (%) | Fat content (%) |

|---|---|---|---|---|---|---|---|---|

| Zhongjiazao 17 | indica | 95.0 ± 4.4 a | 20.3 ± 0.7 b | T | 85.2 ± 0.2 bc | 27.7 ± 0.4 a | 8.3 ± 0.1 c | 0.3 ± 0.0 cd |

| C | 85.7 ± 0.3 ab | 25.8 ± 0.1 c | 6.6 ± 0.0 g | 0.4 ± 0.1 c | ||||

| Zhongzao 39 | indica | 98.3 ± 0.6 a | 22.4 ± 0.5 a | T | 82.6 ± 0.4 ef | 25.4 ± 0.2 c | 9.7 ± 0.3 a | 0.6 ± 0.0 b |

| C | 81.5 ± 1.1 f | 23.4 ± 0.1 e | 8.0 ± 0.0 d | 1.1 ± 0.1 a | ||||

| Zaojian 177 | indica | 83.3 ± 1.5 b | 18.2 ± 0.6 c | T | 85.8 ± 0.9 ab | 26.3 ± 0.1 b | 9.7 ± 0.2 a | 0.3 ± 0.0 cd |

| C | 85.5 ± 0.5 ab | 24.8 ± 0.4 d | 7.4 ± 0.1 e | 0.4 ± 0.0 c | ||||

| Zhonghua 11 | japonica | 14.7 ± 2.5 d | 7.9 ± 0.8 d | T | 85.9 ± 0.6 ab | 17.3 ± 0.2 f | 9.5 ± 0.1 b | 0.3 ± 0.0 d |

| C | 86.7 ± 0.8 a | 15.7 ± 0.1 g | 6.9 ± 0.0 f | 0.7 ± 0.0 b | ||||

| Nangeng 46 | japonica | 20.0 ± 2.0 c | 5.0 ± 0.2 e | T | 84.1 ± 0.5 cd | 12.6 ± 0.4 i | 8.3 ± 0.1 c | 0.2 ± 0.1 d |

| C | 83.0 ± 0.6 de | 10.3 ± 0.3 j | 7.1 ± 0.2 f | 0.3 ± 0.0 cd | ||||

| Qiutianxiaoding | japonica | 7.0 ± 1.0 e | 0.9 ± 0.1 f | T | 85.6 ± 0.6 ab | 15.7 ± 0.3 g | 8.4 ± 0.1 c | 0.4 ± 0.0 c |

| C | 86.2 ± 0.8 ab | 13.9 ± 0.2 h | 6.3 ± 0.1 h | 0.6 ± 0.0 b |

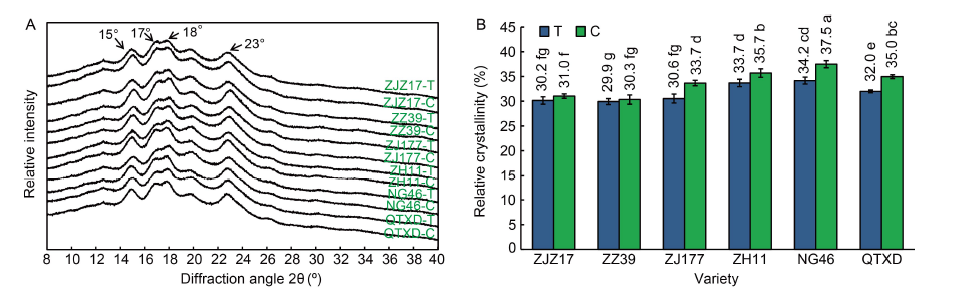

Fig. 1. X-ray diffraction patterns and relative crystallinities of starch granules in translucent (T) and chalky (C) flour from six rice varieties. A, X-ray diffraction patterns of starch granules in T and C flour from six rice varieties.. B, Relative crystallinity of starch granules. Data are Mean ± SD (n = 3). Different lowercase letters behind the mean values indicate significant difference at P < 0.05. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

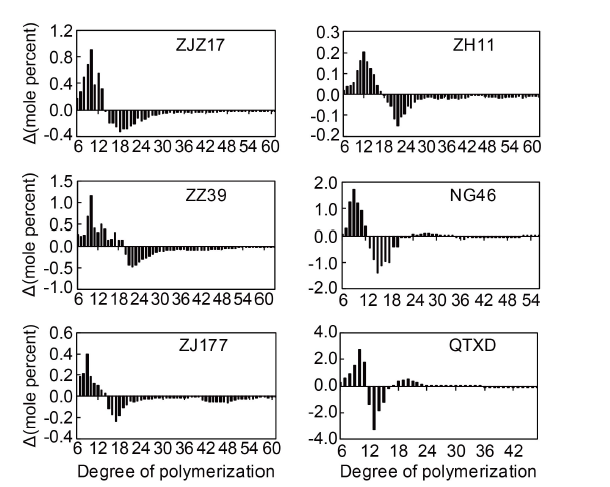

Fig. 2. Starch chain length distribution in chalky and translucent flour from six rice varieties indicated by mole percent of chalky flour minus mole percent of translucent flour [Δ(mole percent)]. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

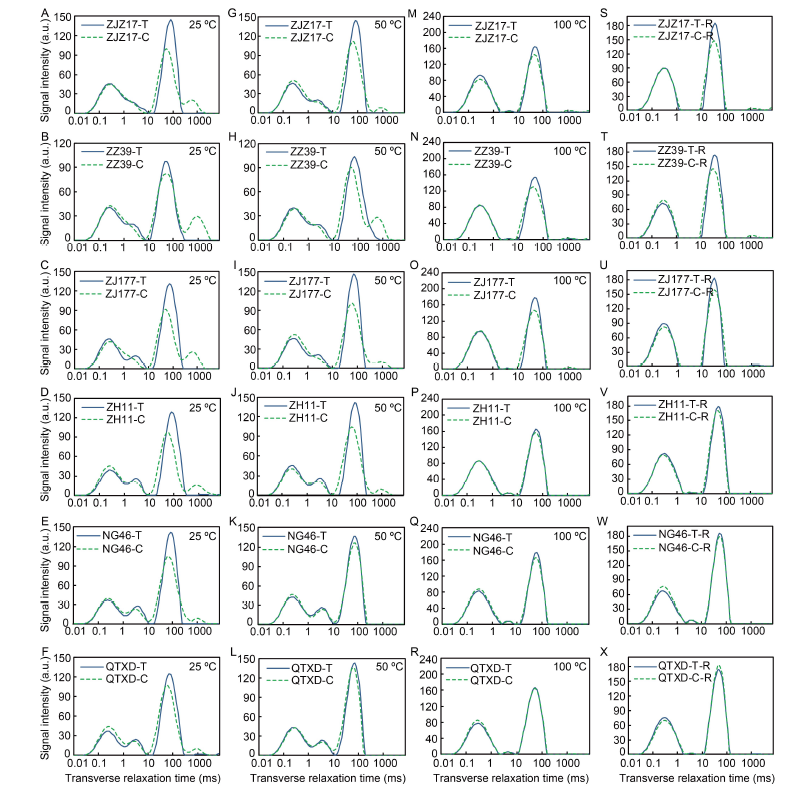

Fig. 3. Water states in translucent (T) and chalky (C) flour determined by nuclear magnetic resonance. A-F, Water states in translucent and chalky flour after soaking in water at 25 ºC for 0.5 h. G-L, Water states in translucent and chalky flour after soaking in water at 50 ºC for 0.5 h. M-R, Water states in translucent and chalky flour after cooking at 100 ºC in a water bath for 0.5 h. S-X, Water states in translucent and chalky flour after retrogradation at 4 ºC in a refrigerator for 24 h. Transverse relaxation time of 0.01-10, 10-400 and 400-6 000 ms represents bound water, constructural water and free water, respectively. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

| Rice flour | Bound water (%) | Constructural water (%) | Free water (%) | Bound water (%) | Constructural water (%) | Free water (%) |

|---|---|---|---|---|---|---|

| Soaking in water at 25 ºC for 0.5 h | Soaking in water at 50 ºC for 0.5 h | |||||

| ZJZ17-T | 38.3 ± 0.3 bc | 61.7 ± 0.5 b | / | 38.5 ± 0.3 efg | 61.5 ± 0.3 b | / |

| ZJZ17-C | 38.7 ± 0.5 b | 53.4 ± 0.6 e | 8.0 ± 0.4 c | 39.3 ± 0.7 bcde | 58.2 ± 0.3 d | 2.5 ± 0.3 c |

| ZZ39-T | 37.7 ± 0.3 c | 62.3 ± 0.3 b | / | 37.8 ± 0.8 fg | 62.2 ± 0.8 a | / |

| ZZ39-C | 38.2 ± 0.3 bc | 46.9 ± 0.5 h | 14.9 ± 0.5 a | 39.0 ± 0.8 cde | 48.3 ± 0.4 f | 12.7 ± 0.8 a |

| ZJ177-T | 37.9 ± 0.3 c | 61.9 ± 0.8 b | 0.2 ± 0.1 f | 39.9 ± 0.1 abc | 60.1 ± 0.1 c | / |

| ZJ177-C | 37.8 ± 0.1 c | 50.6 ± 0.4 g | 11.6 ± 0.4 b | 40.6 ± 0.7 a | 56.3 ± 0.7 e | 3.1 ± 0.7 c |

| ZH11-T | 37.0 ± 0.7 d | 62.4 ± 0.4 b | 0.6 ± 0.4 f | 39.7 ± 0.3 abc | 60.3 ± 0.3 c | / |

| ZH11-C | 40.7 ± 0.2 a | 51.7 ± 0.4 f | 7.6 ± 0.7 c | 39.8 ± 0.3 abc | 56.4 ± 0.1 e | 3.8 ± 0.5 b |

| NG46-T | 36.5 ± 0.1 de | 63.5 ± 0.1 a | / | 38.8 ± 0.3 de | 61.2 ± 0.3 b | / |

| NG46-C | 37.9 ± 0.2 c | 59.4 ± 0.6 c | 2.7 ± 0.1 e | 40.2 ± 0.3 ab | 59.8 ± 0.3 c | / |

| QTXD-T | 36.0 ± 0.2 e | 63.7 ± 0.2 a | 0.3 ± 0.1 f | 37.7 ± 0.1 g | 62.3 ± 0.1 a | / |

| QTXD-C | 38.3 ± 0.2 bc | 58.0 ± 0.1 d | 3.7 ± 0.7 d | 38.7 ± 0.3 ef | 61.3 ± 0.3 b | / |

| Cooking in 100 ºC boiling water for 0.5 h | Retrogradation at 4 ºC for 24 h | |||||

| ZJZ17-T | 45.3 ± 0.5 b | 54.7 ± 0.4 d | / | 42.5 ± 0.2 b | 57.5 ± 0.2 d | / |

| ZJZ17-C | 45.3 ± 0.7 b | 53.0 ± 0.6 e | 1.7 ± 0.3 a | 43.6 ± 0.3 a | 54.7 ± 0.6 e | 1.7 ± 0.7 a |

| ZZ39-T | 42.8 ± 0.3 d | 57.2 ± 0.4 b | / | 37.7 ± 0.6 f | 62.3 ± 0.5 a | / |

| ZZ39-C | 42.7 ± 0.6 d | 55.4 ± 0.0 c | 1.9 ± 0.4 a | 40.2 ± 0.3 d | 58.1 ± 0.2 cd | 1.7 ± 0.6 a |

| ZJ177-T | 45.4 ± 0.4 b | 54.6 ± 0.6 d | / | 42.4 ± 0.3 b | 57.5 ± 0.1 d | 0.1 ± 0.2 b |

| ZJ177-C | 46.2 ± 0.4 a | 52.6 ± 0.2 e | 1.2 ± 0.2 b | 43.2 ± 0.2 a | 55.2 ± 0.3 e | 1.6 ± 0.5 a |

| ZH11-T | 43.9 ± 0.5 c | 56.1 ± 0.5 c | / | 41.2 ± 0.3 c | 58.8 ± 0.3 c | / |

| ZH11-C | 44.4 ± 0.9 c | 55.7 ± 0.8 c | / | 42.5 ± 0.8 b | 57.5 ± 0.8 d | / |

| NG46-T | 42.1 ± 0.3 d | 57.9 ± 0.4 b | / | 37.8 ± 0.4 f | 62.2 ± 0.4 a | / |

| NG46-C | 44.3 ± 0.1 c | 55.7 ± 0.1 c | / | 41.2 ± 0.5 c | 58.8 ± 0.5 c | / |

| QTXD-T | 41.1 ± 0.1 e | 58.9 ± 0.1 a | / | 38.6 ± 0.2 e | 61.4 ± 0.2 b | / |

| QTXD-C | 42.7 ± 0.3 d | 57.3 ± 0.3 b | / | 39.0 ± 0.5 e | 61.0 ± 0.5 b | / |

Table 2. Proportions of different water states in translucent (T) and chalky (C) flour from six rice varieties after four treatments.

| Rice flour | Bound water (%) | Constructural water (%) | Free water (%) | Bound water (%) | Constructural water (%) | Free water (%) |

|---|---|---|---|---|---|---|

| Soaking in water at 25 ºC for 0.5 h | Soaking in water at 50 ºC for 0.5 h | |||||

| ZJZ17-T | 38.3 ± 0.3 bc | 61.7 ± 0.5 b | / | 38.5 ± 0.3 efg | 61.5 ± 0.3 b | / |

| ZJZ17-C | 38.7 ± 0.5 b | 53.4 ± 0.6 e | 8.0 ± 0.4 c | 39.3 ± 0.7 bcde | 58.2 ± 0.3 d | 2.5 ± 0.3 c |

| ZZ39-T | 37.7 ± 0.3 c | 62.3 ± 0.3 b | / | 37.8 ± 0.8 fg | 62.2 ± 0.8 a | / |

| ZZ39-C | 38.2 ± 0.3 bc | 46.9 ± 0.5 h | 14.9 ± 0.5 a | 39.0 ± 0.8 cde | 48.3 ± 0.4 f | 12.7 ± 0.8 a |

| ZJ177-T | 37.9 ± 0.3 c | 61.9 ± 0.8 b | 0.2 ± 0.1 f | 39.9 ± 0.1 abc | 60.1 ± 0.1 c | / |

| ZJ177-C | 37.8 ± 0.1 c | 50.6 ± 0.4 g | 11.6 ± 0.4 b | 40.6 ± 0.7 a | 56.3 ± 0.7 e | 3.1 ± 0.7 c |

| ZH11-T | 37.0 ± 0.7 d | 62.4 ± 0.4 b | 0.6 ± 0.4 f | 39.7 ± 0.3 abc | 60.3 ± 0.3 c | / |

| ZH11-C | 40.7 ± 0.2 a | 51.7 ± 0.4 f | 7.6 ± 0.7 c | 39.8 ± 0.3 abc | 56.4 ± 0.1 e | 3.8 ± 0.5 b |

| NG46-T | 36.5 ± 0.1 de | 63.5 ± 0.1 a | / | 38.8 ± 0.3 de | 61.2 ± 0.3 b | / |

| NG46-C | 37.9 ± 0.2 c | 59.4 ± 0.6 c | 2.7 ± 0.1 e | 40.2 ± 0.3 ab | 59.8 ± 0.3 c | / |

| QTXD-T | 36.0 ± 0.2 e | 63.7 ± 0.2 a | 0.3 ± 0.1 f | 37.7 ± 0.1 g | 62.3 ± 0.1 a | / |

| QTXD-C | 38.3 ± 0.2 bc | 58.0 ± 0.1 d | 3.7 ± 0.7 d | 38.7 ± 0.3 ef | 61.3 ± 0.3 b | / |

| Cooking in 100 ºC boiling water for 0.5 h | Retrogradation at 4 ºC for 24 h | |||||

| ZJZ17-T | 45.3 ± 0.5 b | 54.7 ± 0.4 d | / | 42.5 ± 0.2 b | 57.5 ± 0.2 d | / |

| ZJZ17-C | 45.3 ± 0.7 b | 53.0 ± 0.6 e | 1.7 ± 0.3 a | 43.6 ± 0.3 a | 54.7 ± 0.6 e | 1.7 ± 0.7 a |

| ZZ39-T | 42.8 ± 0.3 d | 57.2 ± 0.4 b | / | 37.7 ± 0.6 f | 62.3 ± 0.5 a | / |

| ZZ39-C | 42.7 ± 0.6 d | 55.4 ± 0.0 c | 1.9 ± 0.4 a | 40.2 ± 0.3 d | 58.1 ± 0.2 cd | 1.7 ± 0.6 a |

| ZJ177-T | 45.4 ± 0.4 b | 54.6 ± 0.6 d | / | 42.4 ± 0.3 b | 57.5 ± 0.1 d | 0.1 ± 0.2 b |

| ZJ177-C | 46.2 ± 0.4 a | 52.6 ± 0.2 e | 1.2 ± 0.2 b | 43.2 ± 0.2 a | 55.2 ± 0.3 e | 1.6 ± 0.5 a |

| ZH11-T | 43.9 ± 0.5 c | 56.1 ± 0.5 c | / | 41.2 ± 0.3 c | 58.8 ± 0.3 c | / |

| ZH11-C | 44.4 ± 0.9 c | 55.7 ± 0.8 c | / | 42.5 ± 0.8 b | 57.5 ± 0.8 d | / |

| NG46-T | 42.1 ± 0.3 d | 57.9 ± 0.4 b | / | 37.8 ± 0.4 f | 62.2 ± 0.4 a | / |

| NG46-C | 44.3 ± 0.1 c | 55.7 ± 0.1 c | / | 41.2 ± 0.5 c | 58.8 ± 0.5 c | / |

| QTXD-T | 41.1 ± 0.1 e | 58.9 ± 0.1 a | / | 38.6 ± 0.2 e | 61.4 ± 0.2 b | / |

| QTXD-C | 42.7 ± 0.3 d | 57.3 ± 0.3 b | / | 39.0 ± 0.5 e | 61.0 ± 0.5 b | / |

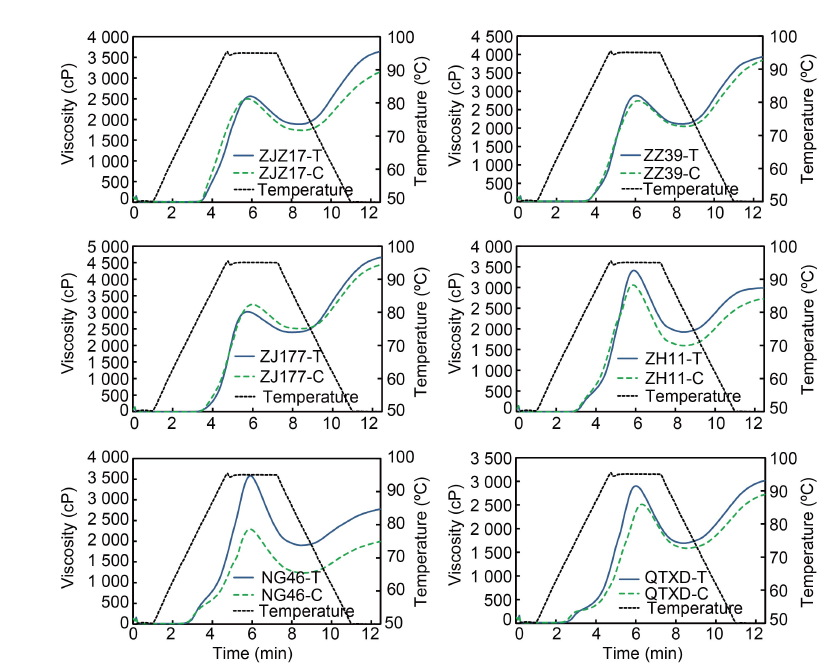

Fig. 4. Rapid Visco Analyser profiles of translucent (T) and chalky (C) flour from six rice varieties. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

| Rice flour | Onset temperature (To) (ºC) | Peak temperature (ºC) | End temperature (Te) (ºC) | Te-To (ºC) | Gelatinization enthalpy (J/g) |

|---|---|---|---|---|---|

| ZJZ17-T | 70.3 ± 0.0 d | 75.2 ± 0.0 c | 80.5 ± 0.2 c | 10.2 ± 0.2 f | 8.6 ± 0.4 de |

| ZJZ17-C | 71.4 ± 0.1 b | 75.1 ± 0.1 c | 79.8 ± 0.1 e | 8.3 ± 0.1 i | 11.6 ± 0.1 a |

| ZZ39-T | 71.6 ± 0.1 b | 76.2 ± 0.0 b | 81.0 ± 0.1 b | 9.5 ± 0.1 g | 8.3 ± 0.4 e |

| ZZ39-C | 73.2 ± 0.1 a | 77.0 ± 0.0 a | 81.7 ± 0.1 a | 8.5 ± 0.2 hi | 10.9 ± 0.4 b |

| ZJ177-T | 69.8 ± 0.1 e | 74.5 ± 0.0 d | 80.1 ± 0.1 d | 10.3 ± 0.2 f | 8.3 ± 0.2 e |

| ZJ177-C | 70.8 ± 0.0 c | 74.8 ± 0.0 cd | 79.5 ± 0.1 e | 8.7 ± 0.1 h | 10.7 ± 0.0 b |

| ZH11-T | 64.8 ± 0.1 g | 70.8 ± 0.1 e | 78.4 ± 0.2 f | 13.6 ± 0.3 c | 7.4 ± 0.2 g |

| ZH11-C | 65.5 ± 0.1 f | 70.4 ± 0.1 ef | 76.4 ± 0.1 g | 10.9 ± 0.2 e | 9.3 ± 0.2 c |

| NG46-T | 59.8 ± 0.1 k | 66.6 ± 0.0 g | 75.6 ± 0.2 i | 15.8 ± 0.3 a | 6.1 ± 0.1 i |

| NG46-C | 60.8 ± 0.1 j | 67.4 ± 0.1 i | 75.3 ± 0.1 i | 14.5 ± 0.1 b | 7.8 ± 0.1 f |

| QTXD-T | 61.1 ± 0.1 i | 69.1 ± 0.1 g | 75.9 ± 0.2 h | 14.7 ± 0.3 b | 6.8 ± 0.0 h |

| QTXD-C | 62.5 ± 0.1 h | 68.3 ± 0.1 h | 74.9 ± 0.0 j | 12.4 ± 0.1 d | 8.7 ± 0.1 d |

Table 3. Gelatinization properties of transparent (T) and chalky (C) flour from six rice varieties.

| Rice flour | Onset temperature (To) (ºC) | Peak temperature (ºC) | End temperature (Te) (ºC) | Te-To (ºC) | Gelatinization enthalpy (J/g) |

|---|---|---|---|---|---|

| ZJZ17-T | 70.3 ± 0.0 d | 75.2 ± 0.0 c | 80.5 ± 0.2 c | 10.2 ± 0.2 f | 8.6 ± 0.4 de |

| ZJZ17-C | 71.4 ± 0.1 b | 75.1 ± 0.1 c | 79.8 ± 0.1 e | 8.3 ± 0.1 i | 11.6 ± 0.1 a |

| ZZ39-T | 71.6 ± 0.1 b | 76.2 ± 0.0 b | 81.0 ± 0.1 b | 9.5 ± 0.1 g | 8.3 ± 0.4 e |

| ZZ39-C | 73.2 ± 0.1 a | 77.0 ± 0.0 a | 81.7 ± 0.1 a | 8.5 ± 0.2 hi | 10.9 ± 0.4 b |

| ZJ177-T | 69.8 ± 0.1 e | 74.5 ± 0.0 d | 80.1 ± 0.1 d | 10.3 ± 0.2 f | 8.3 ± 0.2 e |

| ZJ177-C | 70.8 ± 0.0 c | 74.8 ± 0.0 cd | 79.5 ± 0.1 e | 8.7 ± 0.1 h | 10.7 ± 0.0 b |

| ZH11-T | 64.8 ± 0.1 g | 70.8 ± 0.1 e | 78.4 ± 0.2 f | 13.6 ± 0.3 c | 7.4 ± 0.2 g |

| ZH11-C | 65.5 ± 0.1 f | 70.4 ± 0.1 ef | 76.4 ± 0.1 g | 10.9 ± 0.2 e | 9.3 ± 0.2 c |

| NG46-T | 59.8 ± 0.1 k | 66.6 ± 0.0 g | 75.6 ± 0.2 i | 15.8 ± 0.3 a | 6.1 ± 0.1 i |

| NG46-C | 60.8 ± 0.1 j | 67.4 ± 0.1 i | 75.3 ± 0.1 i | 14.5 ± 0.1 b | 7.8 ± 0.1 f |

| QTXD-T | 61.1 ± 0.1 i | 69.1 ± 0.1 g | 75.9 ± 0.2 h | 14.7 ± 0.3 b | 6.8 ± 0.0 h |

| QTXD-C | 62.5 ± 0.1 h | 68.3 ± 0.1 h | 74.9 ± 0.0 j | 12.4 ± 0.1 d | 8.7 ± 0.1 d |

| [1] | AACC International Approved Methods of Analysis. 1997. Determination of the pasting properties of rice with the Rapid Visco Analyser: Method 61-02.01. St. Paul, MN, USA: AACC International [2021-11-20]. http://dx.doi.org/10.1094/AACCIntMethod-61-02.01. |

| [2] | Bi S L. 2020. Research and analyses on influence of heating rate and soaking temperature on qualities of rice. Wuxi, China: Jiangnan University. (in Chinese with English abstract) |

| [3] | Cai J W, Man J M, Huang J, Liu Q Q, Wei W X, Wei C X. 2015. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydr Polym, 125: 35-44. |

| [4] | Cai Y C, Li S F, Jiao G A, Sheng Z H, Wu Y W, Shao G N, Xie L H, Peng C, Xu J F, Tang S Q, Wei X J, Hu P S. 2018. OsPK2 encodes a plastidic pyruvate kinase involved in rice endosperm starch synthesis, compound granule formation and grain filling. Plant Biotechnol J, 16(11): 1878-1891. |

| [5] | Chao S F, Cai Y C, Feng B B, Jiao G A, Sheng Z H, Luo J, Tang S Q, Wang J L, Hu P S, Wei X J. 2019. Editing of rice isoamylase gene ISA1 provides insights into its function in starch formation. Rice Sci, 26(2): 77-87. |

| [6] | Cheetham N W H, Tao L P. 1998. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohydr Polym, 36(4): 277-284. |

| [7] | Chen S Q. 2014. Relationship between chalky characters, shapes of grains and the quality at different grain positions of japonica rice. Acta Agric Bor Sin, 29(5): 161-167. (in Chinese with English abstract) |

| [8] | Cheng F M, Zhong L J, Shu Q Y, Huang H H, Shi C H, Wu P. 2002. Studies on the cooking and eating quality properties in chalky milled grains of early indica rice. Acta Agron Sin, 28(3): 363-368. (in Chinese with English abstract) |

| [9] | Cheng F M, Zhong L J, Wang F, Zhang G P. 2005. Differences in cooking and eating properties between chalky and translucent parts in rice grains. Food Chem, 90(1/2): 39-46. |

| [10] | Dong M H, Sang D Z, Wang P, Zhang W J, Yang J C. 2006. Difference in chalky characters of grains at different positions within a rice panicle. Acta Agron Sin, 32(1): 103-111. (in Chinese with English abstract) |

| [11] | Horigane A K, Takahashi H, Maruyama S, Ohtsubo K, Yoshida M. 2006. Water penetration into rice grains during soaking observed by gradient echo magnetic resonance imaging. J Cereal Sci, 44(3): 307-316. |

| [12] | Hou C Y, Seiichi O, Yasuhisa S, Yoshinori K. 2001. State of moisture in rice kernel during cooking process by 1H-NMR measurement. Trans Chin Soc Agric Eng, 17(2): 126-131. (in Chinese with English abstract) |

| [13] | Huang Q L, Ma J, Cai G Z. 2006. Progress of correlation study between rice quality and chalkiness in japonica and indica rice. Chin Agric Sci Bull, 22(1): 81-84. (in Chinese with English abstract) |

| [14] | Jaiswal S, Chibbar R N. 2017. Amylopectin small chain glucans form structure fingerprint that determines botanical origin of starch. Carbohydr Polym, 158: 112-123. |

| [15] | Jane J, Chen Y Y, Lee L F, McPherson A E, Wong K S, Radosavljevic M, Kasemsuwan T. 1999. Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem J, 76(5): 629-637. |

| [16] |

Jenkins P J, Donald A M. 1995. The influence of amylose on starch granule structure. Int J Biol Macromol, 17(6): 315-321.

PMID |

| [17] | Jiao G A, Wei X J, Shao G N, Xie L H, Sheng Z H, Tang S Q, Hu P S. 2014. Impact of rice flour cold-water-soluble fraction removal on gelatinization and pasting properties. Cereal Chem J, 91(5): 473-481. |

| [18] | Kuang N, Zhou W, Zhang X, Zheng H B, Tang Q Y. 2021. The research of ratoon rice on cooking and eating quality and the paste property and starch crystal structure. J Chin Cereals Oils Assoc, 36(1): 21-26. (in Chinese with English abstract) |

| [19] | Li D D, Zheng G P, Zheng Y, Cai Y S, Zhao Y, Pan S J, Huang C L, Wang L, Jiang Y W, Zhong W J, Song Z, Zhou J, Yin D W. 2015. Relationship between chalkiness index and other quality traits in japonica rice. Jiangsu Agric Sci, 43(6): 70-72. (in Chinese with English abstract) |

| [20] | Li S F, Wei X J, Ren Y L, Qiu J H, Jiao G A, Guo X P, Tang S Q, Wan J M, Hu P S. 2017. OsBT1 encodes an ADP-glucose transporter involved in starch synthesis and compound granule formation in rice endosperm. Sci Rep, 7: 40124. |

| [21] | Lisle A J, Martin M, Fitzgerald M A. 2000. Chalky and translucent rice grains differ in starch composition and structure and cooking properties. Cereal Chem J, 77(5): 627-632. |

| [22] | Liu S, Shao G N, Jiao G A, Zhu M D, Wu J M, Cao R J, Chen Y J, Xie L H, Sheng Z H, Tang S Q. 2021. Editing of rice endosperm plastidial phosphorylase gene OsPho1 advances its function in starch synthesis. Rice Sci, 28(3): 209-211. |

| [23] | Liu T Y, Liu C M, Fu G M, Luo S J, Liu W. 2013. Influence of rice protein in rice flour on pasting properties. Sci Technol Food Ind, 34(2): 97-99; 103. (in Chinese) |

| [24] |

Liu X L, Guo T, Wan X Y, Wang H Y, Zhu M Z, Li A L, Su N, Shen Y Y, Mao B G, Zhai H Q, Mao L, Wan J M. 2010. Transcriptome analysis of grain-filling caryopses reveals involvement of multiple regulatory pathways in chalky grain formation in rice. BMC Genomics, 11: 730.

PMID |

| [25] | Luo Y H, Li B, Sun Y J, Guo C C, Xin M W, Li F J, Liu F Y, Yang Z Y, Xu F X, Ma J. 2021. Effects of postponing nitrogen topdressing on yield, chalkiness in different grain positions and tasting quality of hybrid indica rice. China Rice, 27(5): 54-58. (in Chinese with English abstract) |

| [26] | Monsur M B, Cao N, Wei X J, Xie L H, Jiao G A, Tang S Q, Sreenivasulu N, Shao G N, Hu P S. 2021. Improved eating and cooking quality of indic rice cultivar YK17 via adenine base editing of Wxa allele of granule-bound starch synthase I (GBSS I). Rice Sci, 28(5): 427-430. |

| [27] | Patindol J, Wang Y J. 2003. Fine structures and physicochemical properties of starches from chalky and translucent rice kernels. J Agric Food Chem, 51(9): 2777-2784. |

| [28] | Qin F L. 2011. Structural properties and development of starch granule in high-amylose rice endosperm. Yangzhou, China: Yangzhou University. (in Chinese with English abstract) |

| [29] | Shi L L, Zhang X, Ding D L, Wang S W, Cui J. 2016. Study on the relationship between chalky rice content and rice quality. Food Sci Technol, 41(9): 177-180. (in Chinese with English abstract) |

| [30] | Singh N, Sodhi N S, Kaur M, Saxena S K. 2003. Physico-chemical, morphological, thermal, cooking and textural properties of chalky and translucent rice kernels. Food Chem, 82(3): 433-439. |

| [31] | State Food and Drug Administration, National Health and Family Planning Commission of the People’s Republic of China. 2016. National standard for food safety: Determination of protein content in foods: GB 5009.5-2016 [2021-11-20]. http://down.foodmate.net/wap/index.php?moduleid=23&itemid=50381. (in Chinese) |

| [32] | Tang S Z, Shun Y, Jiang Y F, Han X D, Mao B H, Gu M H. 2003. Effect of chalkiness on cooking and eating quality of japonica rice. Jiangsu Agric Sci, 4: 4-5. (in Chinese) |

| [33] | The Ministry of Agriculture of the People’s Republic of China. 2014. Determination of amylose content in rice: Spectrophotometric method: NY/T 2639-2014. Beijing: The Ministry of Agriculture of the People’s Republic of China. (in Chinese) |

| [34] | The Ministry of Agriculture of the People’s Republic of China. 2017. Method for determination of rice quality: NY/T 83-2017 [2021-11-20]. http://www.eshian.com/standards/40834.html. (in Chinese) |

| [35] | Tu X L, Li J, Pan S Y, Wang L F. 2017. Correlation study on rice chalkiness degree and steamed rice cooking quality. Modern Food Sci Technol, 33(12): 210-215. (in Chinese with English abstract) |

| [36] | Vandeputte G E, Delcour J A. 2004. From sucrose to starch granule to starch physical behaviour: A focus on rice starch. Carbohydr Polym, 58(3): 245-266. |

| [37] | Varavinit S, Shobsngob S, Varanyanond W, Chinachoti P, Naivikul O. 2003. Effect of amylose content on gelatinization, retrogradation and pasting properties of flour from different cultivars of Thai rice. Starch/Stärke, 55(9): 410-415. |

| [38] | Wang D Y, Zhang X F, Zhu Z W, Chen N, Min J, Yao Q, Yan J L, Liao X Y. 2005. Correlation analysis of rice grain quality characteristics. Acta Agron Sin, 31(8): 1086-1091. (in Chinese with English abstract) |

| [39] | Wang W, Wei X J, Jiao G A, Chen W Q, Wu Y W, Sheng Z H, Hu S K, Xie L H, Wang J Y, Tang S Q, Hu P S. 2020. GBSS- BINDING PROTEIN, encoding a CBM48 domain-containing protein, affects rice quality and yield. J Integr Plant Biol, 62(7): 948-966. |

| [40] | Wei X J, Jiao G A, Lin H Y, Sheng Z H, Shao G N, Xie L H, Tang S Q, Xu Q G, Hu P S. 2017. GRAIN INCOMPLETE FILLING 2 regulates grain filling and starch synthesis during rice caryopsis development. J Integr Plant Biol, 59(2): 134-153. |

| [41] | Yang X Y. 2015. Physicochemical analysis of rice grain quality from perspective of starch structure. Nanjing, China: Nanjing Agricultural University. (in Chinese with English abstract) |

| [42] | Yu R X, Gu Z Y, Han J Z. 2010. Research on the change of moisture state in rice during soaking process by LF-NMR. Food Ind, 1: 12-15. (in Chinese with English abstract) |

| [43] | Zhang W X, Ma C Y, Yuan Y W, Hu X Q, Chen M X, Zhu Z W. 2021. Current situation and regional difference of rice grain quality in three rice-production superiority areas of China. China Rice, 27(5): 12-18. (in Chinese with English abstract) |

| [44] | Zhang Y D, Zhu Z, Zhao L, Wang C L. 2006. Correlation analysis of chalkiness character and food taste value in rice. Jiangsu Agric Sci, 2: 25-26. (in Chinese) |

| [45] | Zhao Y L, Zhang Y J, Wang J X, Zhang S H, Zhang L M, Li D L, Lv B, Shan L L. 2001. Factor analysis on early japonica rice quality in North China. Acta Agron Sin, 27(4): 538-540. (in Chinese with English abstract) |

| [46] | Zhou S C, Li H, Wang J S, Huang D Q, Xie Z W, Lu D C. 2002. Correlation among eating quality and cooking, apparent and milling qualities of South-China indica rice in the early-cropping season. Acta Agron Sin, 28(3): 397-400. (in Chinese with English abstract) |

| [1] | Koteswara Reddy Chagam, Kimi Lalmuan, Haripriya Sundaramoorthy, Kang Nayoung. Effects of Polishing on Proximate Composition, Physico- Chemical Characteristics, Mineral Composition and Antioxidant Properties of Pigmented Rice [J]. Rice Science, 2017, 24(5): 241-252. |

| [2] | YU Xu-run, ZHOU Liang, XIONG Fei, WANG Zhong. Structural and Histochemical Characterization of Developing Rice Caryopsis [J]. RICE SCIENCE, 2014, 21(3): 142-149. |

| [3] | Liu Qi-hua, Zhou Xue-biao, Yang Lian-qun, Li Tian. Effects of Chalkiness on Cooking, Eating and Nutritional Qualities of Rice in Two indica Varieties [J]. RICE SCIENCE, 2009, 16(2): 161-164 . |

| [4] | XIONG Fei, WANG Zhong, CHENG Gang, WANG Jue . Caryopsis Development and Main Quality Characteristics in Different indica Rice Varieties [J]. RICE SCIENCE, 2005, 12(4): 238-242 . |

| [5] | ZHONG Xu-hua, HUANG Nong-rong. Rice Grain Chalkiness Is Negatively Correlated with Root Activity During Grain Filling [J]. RICE SCIENCE, 2005, 12(3): 192-196 . |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||