Rice Science ›› 2025, Vol. 32 ›› Issue (5): 637-648.DOI: 10.1016/j.rsci.2025.06.007

• Reviews • Previous Articles Next Articles

Ghada Abd Elsattar Mohammed Oraby1( ), Fadillah Putra2, M. Halim Natsir3, Dian Siswanto4, Meshal M. Abdullah5, Ammar Abulibdeh6

), Fadillah Putra2, M. Halim Natsir3, Dian Siswanto4, Meshal M. Abdullah5, Ammar Abulibdeh6

Received:2025-02-02

Accepted:2025-06-16

Online:2025-09-28

Published:2025-10-11

Contact:

Ghada Abd Elsattar Mohammed Oraby (Ghada Abd Elsattar Mohammed Oraby, Fadillah Putra, M. Halim Natsir, Dian Siswanto, Meshal M. Abdullah, Ammar Abulibdeh. Straw Burning Dilemma in Modern Agriculture: A Systematic Review of Driving Factors, Environmental Impacts, and Sustainable Solutions[J]. Rice Science, 2025, 32(5): 637-648.

Add to citation manager EndNote|Ris|BibTeX

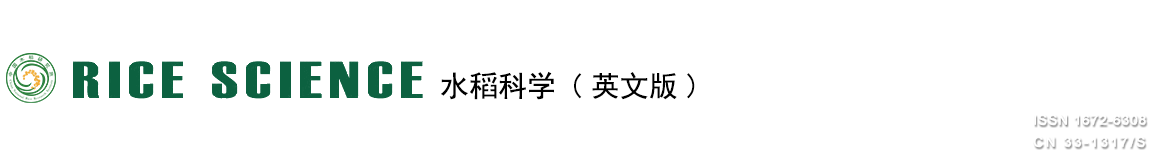

Fig. 1. Mind map of negative impacts of straw burning. The multidimensional negative impacts of straw burning across environmental, agronomic, health, and socio-economic domains. The figure visualizes how straw burning releases multiple atmospheric pollutants, including particulate matter (PM2.5, PM10) (Kim Oanh et al, 2018), carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO2), dioxins, and furans (Romasanta et al, 2017; Mohammad et al, 2023), leading to air quality deterioration, smog formation, and transboundary haze (Romasanta et al, 2017). These emissions exacerbate climate change through elevated greenhouse gas (CO2, CH4, N2O) concentrations and contribute to acid rain, soil acidification, and ecosystem degradation (Romasanta et al, 2017; Zealand et al, 2017; Sakhiya et al, 2023; Zhang et al, 2023). The mind map further illustrates agronomic impacts: burning depletes soil organic carbon, reduces microbial biomass and diversity, disrupts nutrient cycles, and accelerates erosion, undermining long-term soil fertility and agricultural productivity (El-Sobky, 2017; Mohammad et al, 2023; Carmona-Yáñez et al, 2023; Lin et al, 2025). Health consequences are highlighted through increased risks of respiratory diseases, cardiovascular conditions, neurotoxicity, and mortality, particularly among vulnerable populations (Chang et al, 2014; Trivedi et al, 2017; Mohammad et al, 2023). Socioeconomic dimensions include healthcare burdens, productivity losses, biodiversity threats, and broader costs from environmental degradation and resource loss (de Aquino et al, 2017; Laskar et al, 2020; Carmona-Yáñez et al, 2023; Dong et al, 2024; Singh et al, 2025).

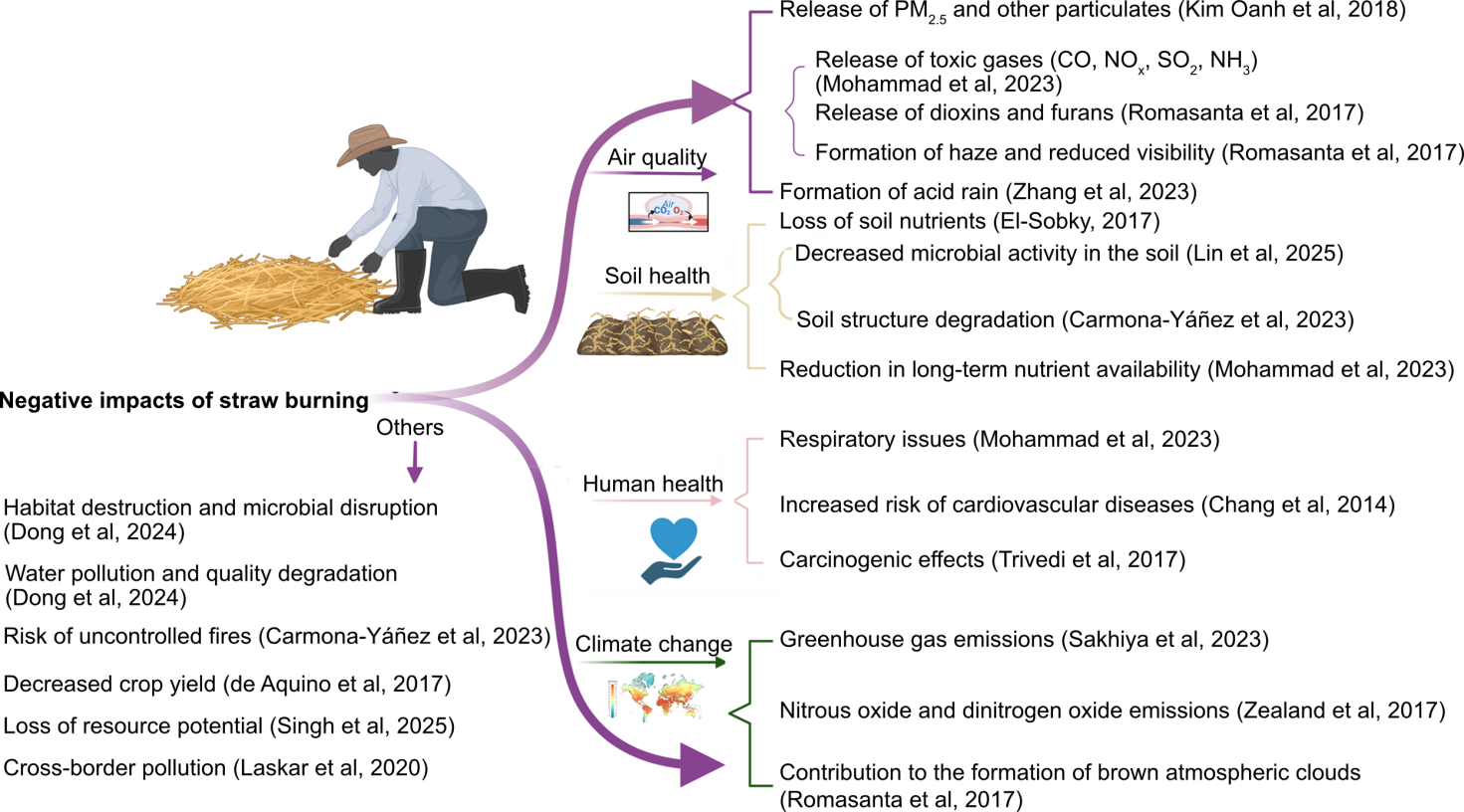

Fig. 2. Solutions to straw burning. The figure summarizes available solutions across technological, agronomic, industrial, and policy dimensions. The figure highlights energy valorization pathways such as bioenergy, biogas, torrefaction, and co-firing, which convert agricultural residues into renewable energy while reducing emissions (Trivedi et al, 2017; Zealand et al, 2017; Yang et al, 2021; Szufa et al, 2023). It also shows agricultural solutions like soil incorporation, mulching, biochar production, and post-harvest field management, which improve soil health and reduce the need for burning (Park et al, 2014; Vega et al, 2014; Niang et al, 2016; Schjønning, 2023). Industrial applications, including pelletization, activated carbon production, and cellulose extraction, offer high-value uses for straw, adding economic incentives (Jeong et al, 2016; Sun et al, 2021; Shao et al, 2023). Furthermore, the figure shows the livestock and food solutions in term of mushroom farming by using straw as a growth medium, and utilizing straw for animal feed (Zhang N et al, 2015; Kim Oanh et al, 2018). Additionally, the figure emphasizes the critical role of enabling policies, financial incentives, and educational programs to promote the adoption of sustainable practices (Giannoccaro et al, 2017; Kim Oanh et al, 2018).

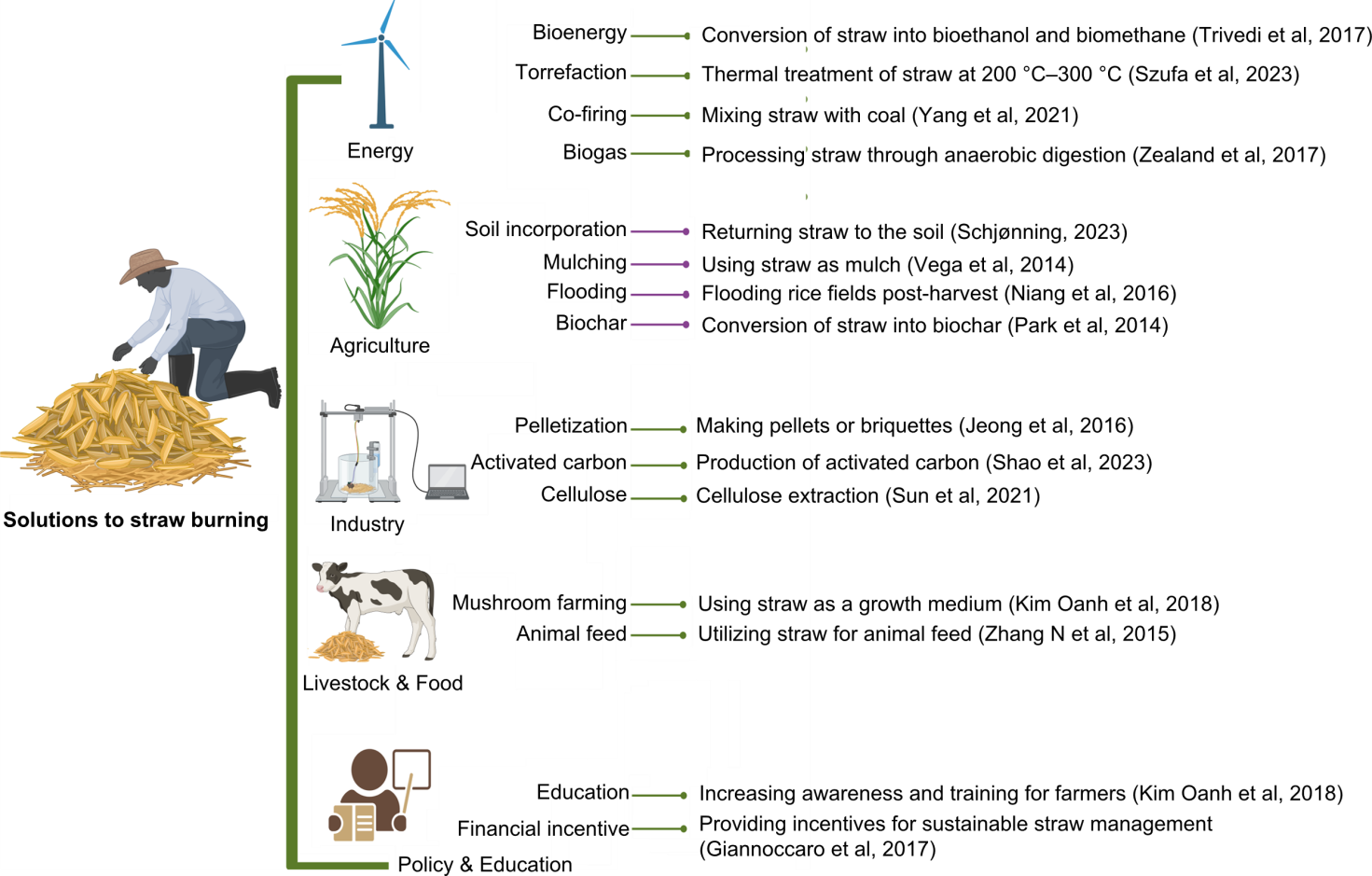

Fig. 3. Multidimensional analysis of straw management solutions. Multidimensional analysis of straw management solutions, evaluating 15 options across four key dimensions: sustainability, implementation feasibility, cost efficiency, and impact. The figure shows that agricultural solutions like soil incorporation and mulching achieve the best overall balance, combining high sustainability, ease of implementation, and cost efficiency. High-tech options such as bioenergy and biochar deliver strong environmental benefits but face higher costs and complexity. Scale description: Cost (1‒5): 1, Very expensive; 5, Very cheap. Impact (1‒5): 1, Minimum impact; 5, Maximum impact. Implementation (1‒5): 1, Very difficult to implement; 5, Very easy to implement. Sustainability (1‒5): 1, Highly unsustainable; 5, Highly sustainable.

| Category | Cause | Citation | Quotation |

|---|---|---|---|

| Time and efficiency constraints | Limited time between harvest and the next growing season | Beig et al, | Average available time between the rice harvesting and wheat sowing is in the range of 20‒30 d depending on the varieties of rice crop |

| The fastest method to clear the land | Kim Oanh et al, | Crop residue open burning is viewed by regional farmers as the cheapest and fastest way to clear land for the next crop | |

| Increased ploughing efficiency | Mohammad et al, | It improves the efficiency of plowing and reduces the need for herbicides and pesticides | |

| Economic constraints | Expensive alternative management costs | Holder et al, | Planting directly in heavy residues requires specialized and expensive machinery |

| Uneconomical straw selling price | Trivedi et al, | Farmers sell paddy straw at an uneconomical price of INR 500 ($7.50) per metric tonne | |

| Lack of incentives to stop burning | Nguyen et al, | Rice growers have little incentive to stop | |

| Infrastructure constraints | Poor storage facilities | Singh G et al, | Mechanized agricultural practices, poor storage facilities |

| Limitations of alternative straw processing | Röder et al, | In the absence of alternatives, the burning continues as a quick and low-cost means of disposal | |

| Lack of alternative technologies | Dong et al, | Due to traditional agricultural practices and technological constraints, the utilization of rice straw remains low | |

| Technical constraints | High silica content | Niang et al, | Rice plants have a high silica content, which prevents rice straw from being used as a compostable bi-product |

| Difficulties in incorporation of straw into the ground | Zealand et al, | Incorporation of rice straw into soil is difficult, due to the relatively short time between harvest and seed | |

| Large volume of straw | El-Sobky, | Burning is the cheapest and easiest way to remove the huge load of straw produced | |

| Agronomic factors | Pest and disease control | Holder et al, | Low-cost method to reduce residues and control or eliminate fungal diseases, pest eggs, and weeds |

| Reduction of soil moisture | Mohammad et al, | Burning straw in the field helps lower the moisture level | |

| Return of nutrients to the soil | Holder et al, | Incineration also provides the added benefit of fertilizing ash by quickly returning minerals to the soil | |

| Socio-cultural factors | Traditional practices that are difficult to change | Nguyen et al, | Despite many efforts to enforce worldwide bans, on-site burning still takes place in many cultivation regions |

| Farmers’ beliefs about the benefits of incineration | El-Sobky, | Rice farmers are used to burning rice straw because they believe there are several benefits obtained for soil fertility | |

| Ease of practice and management | de Aquino et al, | Harvesting systems that have been burned before are easier to practice and require less sustainable management | |

| Agricultural system changes | Increased use of combined harvesting machines | Connor et al, | Increased production and mechanization, such as the use of combined harvesters, which leaves more straw in the field |

| Decrease in the use of straw as animal feed | Ayesh, | The increase in straw burning is also due to the decrease in the use of rice residues as animal feed | |

| Agricultural mechanization | Singh D et al, | Mechanized agricultural practices | |

| Environmental constraints | Weather conditions that do not support natural drying | Mohammad et al, | Farmers do not wait for the soil to dry out after harvesting rice naturally |

| Regulatory constraints | Weak law enforcement | Chang et al, | Open waste burning has been prohibited in Taiwan of China since 1990. However, this regulation is poorly enforced and open crop burning is still commonly used |

| Regional economic factors | Distance from biomass processing facilities | Ortuzar-Iragorri et al, | Part of the cereal straw is being sent to a nearby biomass plant for energy production, other part of this straw, presumably the furthest from the biomass plant, is treated as waste and burned at the field |

| Processing constraints | Long decomposition time | Ortuzar-Iragorri et al, | Wheat growers are reluctant to do so because it takes too long for the straw to decompose and it complicates the seeding and a homogeneous fertilization of the soil |

| Production factors | Increased yield | Gao et al, | With the increase in agricultural yields due to better management and agricultural technology, the proportion of rice straw used for energy and animal feed has decreased substantially |

| Utilization constraints | Limited use of straw | Sun et al, | Due to only the leaves are used as feed, most straw is discarded or burned, causing pollution and resource waste |

| Seasonal factors | Seasonal combustion needs | Zhang et al, | Especially during the harvest season (summer harvest: from late May to early June; autumn harvest: from late October to early November) |

Table 1. Causes of farmers burning straw.

| Category | Cause | Citation | Quotation |

|---|---|---|---|

| Time and efficiency constraints | Limited time between harvest and the next growing season | Beig et al, | Average available time between the rice harvesting and wheat sowing is in the range of 20‒30 d depending on the varieties of rice crop |

| The fastest method to clear the land | Kim Oanh et al, | Crop residue open burning is viewed by regional farmers as the cheapest and fastest way to clear land for the next crop | |

| Increased ploughing efficiency | Mohammad et al, | It improves the efficiency of plowing and reduces the need for herbicides and pesticides | |

| Economic constraints | Expensive alternative management costs | Holder et al, | Planting directly in heavy residues requires specialized and expensive machinery |

| Uneconomical straw selling price | Trivedi et al, | Farmers sell paddy straw at an uneconomical price of INR 500 ($7.50) per metric tonne | |

| Lack of incentives to stop burning | Nguyen et al, | Rice growers have little incentive to stop | |

| Infrastructure constraints | Poor storage facilities | Singh G et al, | Mechanized agricultural practices, poor storage facilities |

| Limitations of alternative straw processing | Röder et al, | In the absence of alternatives, the burning continues as a quick and low-cost means of disposal | |

| Lack of alternative technologies | Dong et al, | Due to traditional agricultural practices and technological constraints, the utilization of rice straw remains low | |

| Technical constraints | High silica content | Niang et al, | Rice plants have a high silica content, which prevents rice straw from being used as a compostable bi-product |

| Difficulties in incorporation of straw into the ground | Zealand et al, | Incorporation of rice straw into soil is difficult, due to the relatively short time between harvest and seed | |

| Large volume of straw | El-Sobky, | Burning is the cheapest and easiest way to remove the huge load of straw produced | |

| Agronomic factors | Pest and disease control | Holder et al, | Low-cost method to reduce residues and control or eliminate fungal diseases, pest eggs, and weeds |

| Reduction of soil moisture | Mohammad et al, | Burning straw in the field helps lower the moisture level | |

| Return of nutrients to the soil | Holder et al, | Incineration also provides the added benefit of fertilizing ash by quickly returning minerals to the soil | |

| Socio-cultural factors | Traditional practices that are difficult to change | Nguyen et al, | Despite many efforts to enforce worldwide bans, on-site burning still takes place in many cultivation regions |

| Farmers’ beliefs about the benefits of incineration | El-Sobky, | Rice farmers are used to burning rice straw because they believe there are several benefits obtained for soil fertility | |

| Ease of practice and management | de Aquino et al, | Harvesting systems that have been burned before are easier to practice and require less sustainable management | |

| Agricultural system changes | Increased use of combined harvesting machines | Connor et al, | Increased production and mechanization, such as the use of combined harvesters, which leaves more straw in the field |

| Decrease in the use of straw as animal feed | Ayesh, | The increase in straw burning is also due to the decrease in the use of rice residues as animal feed | |

| Agricultural mechanization | Singh D et al, | Mechanized agricultural practices | |

| Environmental constraints | Weather conditions that do not support natural drying | Mohammad et al, | Farmers do not wait for the soil to dry out after harvesting rice naturally |

| Regulatory constraints | Weak law enforcement | Chang et al, | Open waste burning has been prohibited in Taiwan of China since 1990. However, this regulation is poorly enforced and open crop burning is still commonly used |

| Regional economic factors | Distance from biomass processing facilities | Ortuzar-Iragorri et al, | Part of the cereal straw is being sent to a nearby biomass plant for energy production, other part of this straw, presumably the furthest from the biomass plant, is treated as waste and burned at the field |

| Processing constraints | Long decomposition time | Ortuzar-Iragorri et al, | Wheat growers are reluctant to do so because it takes too long for the straw to decompose and it complicates the seeding and a homogeneous fertilization of the soil |

| Production factors | Increased yield | Gao et al, | With the increase in agricultural yields due to better management and agricultural technology, the proportion of rice straw used for energy and animal feed has decreased substantially |

| Utilization constraints | Limited use of straw | Sun et al, | Due to only the leaves are used as feed, most straw is discarded or burned, causing pollution and resource waste |

| Seasonal factors | Seasonal combustion needs | Zhang et al, | Especially during the harvest season (summer harvest: from late May to early June; autumn harvest: from late October to early November) |

| [1] | Akbari M Z, Thepnuan D, Wiriya W, et al. 2021. Emission factors of metals bound with PM2.5 and ashes from biomass burning simulated in an open-system combustion chamber for estimation of open burning emissions. Atmos Pollut Res, 12(3): 13-24. |

| [2] | Arunrat N, Sereenonchai S, Sansupa C, et al. 2023. Effect of rice straw and stubble burning on soil physicochemical properties and bacterial communities in central Thailand. Biology, 12(4): 501. |

| [3] | Asadi H, Ghorbani M, Rezaei-Rashti M, et al. 2021. Application of rice husk biochar for achieving sustainable agriculture and environment. Rice Sci, 28(4): 325-343. |

| [4] | Ayesh A. 2023. Burned agricultural biomass, air pollution and crime. J Environ Econ Manag, 122: 102887. |

| [5] | Beig G, Sahu S K, Rathod A, et al. 2021. Role of meteorological regime in mitigating biomass induced extreme air pollution events. Urban Clim, 35: 100756. |

| [6] | Bhattacharyya P, Bisen J, Bhaduri D, et al. 2021. Turn the wheel from waste to wealth: Economic and environmental gain of sustainable rice straw management practices over field burning in reference to India. Sci Total Environ, 775: 145896. |

| [7] | Carmona-Yáñez M D, Francos M, Miralles I, et al. 2023. Short-term impacts of wildfire and post-fire mulching on ecosystem multifunctionality in a semi-arid pine forest. For Ecol Manag, 541: 121000. |

| [8] | Chang S S, Lee W J, Holsen T M, et al. 2014. Emissions of polychlorinated-p-dibenzo dioxin, dibenzofurans (PCDD/Fs) and polybrominated diphenyl ethers (PBDEs) from rice straw biomass burning. Atmos Environ, 94: 573-581. |

| [9] | Chen H, Wang H Y, Zhou S S. 2023. Farmers’ cognition of and satisfaction with policy affect willingness of returning straw to field: Based on evolutionary game perspective. Sustainability, 15(21): 15227. |

| [10] | Chen Q Q, Yang Q, Ye D M. 2020. Regional environment, family’s endowment and straw disposal behavior: A case study of dry farming areas in Gansu Province, China. Chin J Appl Ecol, 31(2): 563-572. (in Chinese with English abstract) |

| [11] | Connor M, de Guia A H, Quilloy R, et al. 2020. When climate change is not psychologically distant: Factors influencing the acceptance of sustainable farming practices in the Mekong River Delta of Vietnam. World Dev Perspect, 18: 100204. |

| [12] | de Aquino G S, de Conti Medina C, da Costa D C, et al. 2017. Sugarcane straw management and its impact on production and development of ratoons. Ind Crops Prod, 102: 58-64. |

| [13] | Dong C F, Cai Q S, Wang C L, et al. 2008. QTL analysis for traits associated with feeding value of straw in rice (Oryza sativa L.). Rice Sci, 15(3): 195-200. |

| [14] | Dong W J, Xu M D, Yang X W, et al. 2024. Rice straw ash and amphibian health: A deep dive into microbiota changes and potential ecological consequences. Sci Total Environ, 926: 171651. |

| [15] | El-Sobky E S E A. 2017. Effect of burned rice straw, phosphorus and nitrogen fertilization on wheat (Triticum aestivum L.). Ann Agric Sci, 62(1): 113-120. |

| [16] | Fernández C, Vega J A, Fontúrbel T. 2016. Reducing post-fire soil erosion from the air: Performance of heli-mulching in a mountainous area on the coast of NW Spain. Catena, 147: 489-495. |

| [17] | Fushimi A, Saitoh K, Hayashi K, et al. 2017. Chemical characterization and oxidative potential of particles emitted from open burning of cereal straws and rice husk under flaming and smoldering conditions. Atmos Environ, 163: 118-127. |

| [18] | Gao R, Jiang W, Gao W D, et al. 2017. Emission inventory of crop residue open burning and its high-resolution spatial distribution in 2014 for Shandong Province, China. Atmos Pollut Res, 8(3): 545-554. |

| [19] | Giang N C, Chien N Q, Khac D V. 2024. Estimation of greenhouse gas emission due to open burning of rice straw using sentinel data. Vietnam J Earth Sci, 46(3): 381-398. |

| [20] | Giannoccaro G, de Gennaro B C, de Meo E, et al. 2017. Assessing farmers’ willingness to supply biomass as energy feedstock: Cereal straw in Apulia (Italy). Energy Econ, 61: 179-185. |

| [21] | Guo H P, Xu S, Wang X T, et al. 2021. Driving mechanism of farmers’ utilization behaviors of straw resources: An empirical study in Jilin Province, the main grain producing region in the northeast part of China. Sustainability, 13(5): 2506. |

| [22] | Guo S Q. 2021. How does straw burning affect urban air quality in China? Am J Agric Econ, 103(3): 1122-1140. |

| [23] | He G J, Liu T, Zhou M G. 2020. Straw burning, PM2.5, and death: Evidence from China. J Dev Econ, 145: 102468. |

| [24] | Holder A L, Gullett B K, Urbanski S P, et al. 2017. Emissions from prescribed burning of agricultural fields in the Pacific Northwest. Atmos Environ, 166: 22-33. |

| [25] | Huang L, Zhu Y H, Wang Q, et al. 2021. Assessment of the effects of straw burning bans in China: Emissions, air quality, and health impacts. Sci Total Environ, 789: 147935. |

| [26] | Jeong C Y, Dodla S K, Wang J J. 2016. Fundamental and molecular composition characteristics of biochars produced from sugarcane and rice crop residues and by-products. Chemosphere, 142: 4-13. |

| [27] | Jha P, Hati K M, Dalal R C, et al. 2020. Soil carbon and nitrogen dynamics in a vertisol following 50 years of no-tillage, crop stubble retention and nitrogen fertilization. Geoderma, 358: 113996. |

| [28] | Kajina W, Rousset P, Chen W H, et al. 2018. Coupled effect of torrefaction and blending on chemical and energy properties for combustion of major open burned agriculture residues in Thailand. Renew Energy, 118: 113-121. |

| [29] | Kim Oanh N T, Permadi D A, Hopke P K, et al. 2018. Annual emissions of air toxics emitted from crop residue open burning in Southeast Asia over the period of 2010-2015. Atmos Environ, 187: 163-173. |

| [30] | Laskar A H, Maurya A S, Singh V, et al. 2020. A new perspective of probing the level of pollution in the megacity Delhi affected by crop residue burning using the triple oxygen isotope technique in atmospheric CO2. Environ Pollut, 263: 114542. |

| [31] | Limmer M A, Linam F A, Seyfferth A L. 2023. The effect of rice residue management on rice paddy Si, Fe, As, and methane biogeochemistry. Sci Total Environ, 903: 166496. |

| [32] | Lin H Y, Zheng J, Zhou M H, et al. 2025. Crop straw incorporation increases the soil carbon stock by improving the soil aggregate structure without stimulating soil heterotrophic respiration. J Integr Agric, 24(4): 1542-1561. |

| [33] | Liu Y Z, Zhang J, Zhuang M H. 2021. Bottom-up re-estimations of greenhouse gas and atmospheric pollutants derived from straw burning of three cereal crops production in China based on a national questionnaire. Environ Sci Pollut Res Int, 28(46): 65410-65415. |

| [34] | Lopes A A, Viriyavipart A, Tasneem D. 2020. The role of social influence in crop residue management: Evidence from Northern India. Ecol Econ, 169: 106563. |

| [35] | Mohammad L, Bandyopadhyay J, Sk R, et al. 2023. Estimation of agricultural burned affected area using NDVI and dNBR satellite-based empirical models. J Environ Manag, 343: 118226. |

| [36] | Morsy F A, El-Sheikh S M, Barhoum A. 2019. Nano-silica and SiO2/ CaCO3 nanocomposite prepared from semi-burned rice straw ash as modified papermaking fillers. Arab J Chem, 12(7): 1186-1196. |

| [37] | Mothe S, Polisetty V R, Sridhar P, et al. 2022. Comparison of GHG emissions from open field burning and anaerobic digestion of rice straw. Environ Technol, 2022: 2153749. |

| [38] | Mueller-Niggemann C, Lehndorff E, Amelung W, et al. 2016. Source and depth translocation of combustion residues in Chinese agroecosystems determined from parallel polycyclic aromatic hydrocarbon (PAH) and black carbon (BC) analysis. Org Geochem, 98: 27-37. |

| [39] | Nguyen M N, Dam T T N, Nguyen A T Q, et al. 2021. Arsenic in rice straw phytoliths: Encapsulation and release properties. Appl Geochem, 127: 104907. |

| [40] | Niang A, Pernollet C A, Gauthier-Clerc M, et al. 2016. A cost-benefit analysis of rice field winter flooding for conservation purposes in Camargue, Southern France. Agric Ecosyst Environ, 231: 193-205. |

| [41] | Ortuzar-Iragorri M A, Aizpurua A, Castellón A, et al. 2015. What can be done with cereal straw in Alava? In: Edwards D, Olroyd G. Agriculture and Climate Change:Adapting Crops to Increased Uncertainty (AGRI 2015). 4th International Conference on Agriculture and Horticulture (AGRI), February 15-17, 2015. Amsterdam, the Netherlands: Procedia Environmental Sciences, 29: 221-222. |

| [42] | Parihar D S, Narang M K, Dogra B, et al. 2023. Rice residue burning in Northern India: An assessment of environmental concerns and potential solutions: A review. Environ Res Commun, 5(6): 062001. |

| [43] | Park J, Lee Y, Ryu C, et al. 2014. Slow pyrolysis of rice straw: Analysis of products properties, carbon and energy yields. Bioresour Technol, 155: 63-70. |

| [44] | Park S, Yu G H, Bae M S. 2020. Effects of combustion condition and biomass type on the light absorption of fine organic aerosols from fresh biomass burning emissions over Korea. Environ Pollut, 265: 114841. |

| [45] | Quispe I, Navia R, Kahhat R. 2019. Life cycle assessment of rice husk as an energy source: A Peruvian case study. J Clean Prod, 209: 1235-1244. |

| [46] | Ren J Q, Yu P X, Xu X H. 2019. Straw utilization in China: Status and recommendations. Sustainability, 11(6): 1762. |

| [47] | Röder M, Jamieson C, Thornley P. 2020. (Stop) burning for biogas. Enabling positive sustainability trade-offs with business models for biogas from rice straw. Biomass Bioenergy, 138: 105598. |

| [48] | Romasanta R R, Sander B O, Gaihre Y K, et al. 2017. How does burning of rice straw affect CH4 and N2O emissions? A comparative experiment of different on-field straw management practices. Agric Ecosyst Environ, 239: 143-153. |

| [49] | Roper M M, Kerr R, Ward P R, et al. 2021. Changes in soil properties and crop performance on stubble-burned and cultivated water-repellent soils can take many years following reversion to no-till and stubble retention. Geoderma, 402: 115361. |

| [50] | Sakhiya A K, Vijay V K, Kaushal P. 2023. Development of rice straw biochar through pyrolysis to improve drinking water quality in arsenic and manganese contaminated areas. Surf Interfaces, 36: 102582. |

| [51] | Schjønning P. 2023. Straw management in small grain cereal crop production: The long-term effects on soil carbon and soil pore characteristics. Geoderma, 435: 116499. |

| [52] | Shao S, Zhang B, Wang Y, et al. 2023. Dry biorefinery conversion of cadmium-contaminated rice grain and straw to ethanol with complete collection and recycling of cadmium. Ind Crops Prod, 197: 116550. |

| [53] | Shen G F. 2016. Changes from traditional solid fuels to clean household energies: Opportunities in emission reduction of primary PM2.5 from residential cookstoves in China. Biomass Bioenergy, 86: 28-35. |

| [54] | Singh D, Kundu N, Ghosh S. 2021. Mapping rice residues burning and generated pollutants using Sentinel-2 data over northern part of India. Remote Sens Appl Soc Environ, 22: 100486. |

| [55] | Singh G, Gupta M K, Chaurasiya S, et al. 2021. Rice straw burning: A review on its global prevalence and the sustainable alternatives for its effective mitigation. Environ Sci Pollut Res Int, 28: 32125-32155. |

| [56] | Singh J, Bhattu M, Liew R K, et al. 2025. Transforming rice straw waste into biochar for advanced water treatment and soil amendment applications. Environ Technol Innov, 37: 103932. |

| [57] | Sun J, Cui L H, Gao Y H, et al. 2021. Environmental application of magnetic cellulose derived from Pennisetum sinese Roxb for efficient tetracycline removal. Carbohydr Polym, 251: 117004. |

| [58] | Szufa S, Piersa P, Junga R, et al. 2023. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy, 263: 125918. |

| [59] | Trivedi A, Verma A R, Kaur S, et al. 2017. Sustainable bio-energy production models for eradicating open field burning of paddy straw in Punjab, India. Energy, 127: 310-317. |

| [60] | Vega J A, Fernández C, Fonturbel T, et al. 2014. Testing the effects of straw mulching and herb seeding on soil erosion after fire in a gorse shrubland. Geoderma, 223: 79-87. |

| [61] | Wang W Y, Akhtar K, Ren G X, et al. 2019. Impact of straw management on seasonal soil carbon dioxide emissions, soil water content, and temperature in a semi-arid region of China. Sci Total Environ, 652: 471-482. |

| [62] | Xia L L, Lam S K, Wolf B, et al. 2018. Trade-offs between soil carbon sequestration and reactive nitrogen losses under straw return in global agroecosystems. Glob Chang Biol, 24(12): 5919-5932. |

| [63] | Xu C, You C. 2023. Agricultural expansion dominates rapid increases in cropland fires in Asia. Environ Int, 179: 108189. |

| [64] | Yang Q, Wang T, Wang J W, et al. 2021. Combustion, emission and slagging characteristics for typical agricultural crop straw usage in heating plants. Thermochim Acta, 702: 178979. |

| [65] | Zealand A M, Roskilly A P, Graham D W. 2017. Effect of feeding frequency and organic loading rate on biomethane production in the anaerobic digestion of rice straw. Appl Energy, 207: 156-165. |

| [66] | Zhang H F, Hu J, Qi Y X, et al. 2017. Emission characterization, environmental impact, and control measure of PM2.5 emitted from agricultural crop residue burning in China. J Clean Prod, 149: 629-635. |

| [67] | Zhang N, Zhou P, Kung C C. 2015. Total-factor carbon emission performance of the Chinese transportation industry: A bootstrapped non-radial Malmquist index analysis. Renew Sustain Energy Rev, 41: 584-593. |

| [68] | Zhang T R, Wooster M J, Green D C, et al. 2015. New field-based agricultural biomass burning trace gas, PM2.5, and black carbon emission ratios and factors measured in situ at crop residue fires in Eastern China. Atmos Environ, 121: 22-34. |

| [69] | Zhang Y, Li J H, Tan J Y, et al. 2023. An overview of the direct and indirect effects of acid rain on plants: Relationships among acid rain, soil, microorganisms, and plants. Sci Total Environ, 873: 162388. |

| [70] | Zhu H, Ao Y B, Xu H, et al. 2021. Determinants of farmers’ intention of straw recycling: A comparison analysis based on different pro-environmental publicity modes. Int J Environ Res Public Health, 18(21): 11304. |

| [71] | Zhu Y H, Huang L, Li Y M, et al. 2022. Greenhouse gas emissions from open biomass burning and the co-reduction due to straw burning bans in China. Acta Sci Circumstantiae, 42(10): 160-169. (in Chinese with English abstract) |

| [72] | Zhuang M H, Zhang J, Kong Z Y, et al. 2020. Potential environmental benefits of substituting nitrogen and phosphorus fertilizer with usable crop straw in China during 2000-2017. J Clean Prod, 267: 122125. |

| [1] | Priyanka Negi, Jagadish Rane, Rajendra Sadashiv Wagh, Tukaram Jayaram Bhor, Dipti Digambar Godse, Priyanka Jadhav, C. Anilkumar, Dasari Sreekanth, K. Sammi Reddy, Sharad Ramrao Gadakh, K. M. Boraih, C. B. Harisha, P. S. Basavaraj. Direct-Seeded Rice: Genetic Improvement of Game-Changing Traits for Better Adaption [J]. Rice Science, 2024, 31(4): 417-433. |

| [2] | Konan Jean-Yves N’guessan, Botou Adahi, Arthur-Brice Konan-Waidhet, Satoh Masayoshi, Nogbou Emmanuel Assidjo. Assessment of Climate Change Impact on Water Requirement and Rice Productivity [J]. Rice Science, 2023, 30(4): 276-293. |

| [3] | Stephan Nascente Adriano, Fernando Stone Luis. Cover Crops as Affecting Soil Chemical and Physical Properties and Development of Upland Rice and Soybean Cultivated in Rotation [J]. Rice Science, 2018, 25(6): 340-349. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||