Rice Science ›› 2016, Vol. 23 ›› Issue (5): 274-281.DOI: 10.1016/j.rsci.2016.08.005

• Orginal Article • Previous Articles Next Articles

Leewatchararongjaroen Jitranut, Anuntagool Jirarat( )

)

Received:2015-10-12

Accepted:2015-12-08

Online:2016-09-05

Published:2016-06-12

Leewatchararongjaroen Jitranut, Anuntagool Jirarat. Effects of Dry-Milling and Wet-Milling on Chemical, Physical and Gelatinization Properties of Rice Flour[J]. Rice Science, 2016, 23(5): 274-281.

Add to citation manager EndNote|Ris|BibTeX

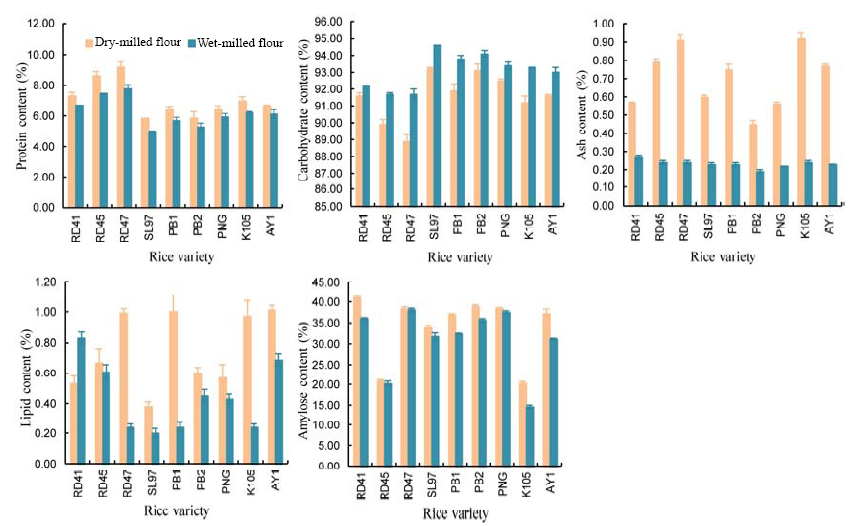

Fig. 1. Chemical composition of dry-milled rice flour and wet-milled rice flour. RD41, Rice Department 41; RD45, Rice Department 45; RD47, Rice Department 47; SL97, Shaw Lung 97; PB1, Prachin Buri 1; PB2, Prachin Buri 2; PNG, Plai Ngahm Prachin Buri; K105, Khao Dawk Mali 105; AY1, Ayutthaya 1.

| Variety | Dry-milled rice flour | Wet-milled rice flour | |||

|---|---|---|---|---|---|

| Dry flour | Alcohol | Dry flour | Alcohol | ||

| RD41 | 81.8 ± 0.7 bc | 31.5 ± 0.1 h | 40.6 ± 1.1 i | 27.7 ± 0.3 i | |

| RD45 | 86.2 ± 0.4 a | 66.7 ± 0.4 b | 56.9 ± 0.5 g | 27.2 ± 0.3 j | |

| RD47 | 80.2 ± 0.5 c | 57.9 ± 0.1 c | 26.5 ± 0.2 l | 24.9 ± 0.2 k | |

| SL97 | 83.2 ± 0.3 b | 73.1 ± 0.3 a | 38.0 ± 0.6 j | 18.6 ± 0.2 o | |

| PB1 | 76.2 ± 0.8 d | 34.4 ± 0.0 g | 23.5 ± 0.2 m | 19.3 ± 0.3 m | |

| PB2 | 66.1 ± 0.4 f | 34.2 ± 0.2 g | 31.4 ± 0.6 k | 22.2 ± 0.2 l | |

| PNG | 80.5 ± 0.5 c | 53.2 ± 0.2 d | 22.7 ± 0.4 m | 19.1 ± 0.1 mn | |

| K105 | 87.2 ± 0.6 a | 35.2 ± 0.2 f | 19.8 ± 0.1 n | 18.9 ± 0.1 no | |

| AY1 | 68.3 ± 0.4 e | 41.1 ± 0.2 e | 42.9 ± 5.6 h | 24.6 ± 0.2 k | |

Table 1 Particle size of dry- and wet-milled rice flour. μm

| Variety | Dry-milled rice flour | Wet-milled rice flour | |||

|---|---|---|---|---|---|

| Dry flour | Alcohol | Dry flour | Alcohol | ||

| RD41 | 81.8 ± 0.7 bc | 31.5 ± 0.1 h | 40.6 ± 1.1 i | 27.7 ± 0.3 i | |

| RD45 | 86.2 ± 0.4 a | 66.7 ± 0.4 b | 56.9 ± 0.5 g | 27.2 ± 0.3 j | |

| RD47 | 80.2 ± 0.5 c | 57.9 ± 0.1 c | 26.5 ± 0.2 l | 24.9 ± 0.2 k | |

| SL97 | 83.2 ± 0.3 b | 73.1 ± 0.3 a | 38.0 ± 0.6 j | 18.6 ± 0.2 o | |

| PB1 | 76.2 ± 0.8 d | 34.4 ± 0.0 g | 23.5 ± 0.2 m | 19.3 ± 0.3 m | |

| PB2 | 66.1 ± 0.4 f | 34.2 ± 0.2 g | 31.4 ± 0.6 k | 22.2 ± 0.2 l | |

| PNG | 80.5 ± 0.5 c | 53.2 ± 0.2 d | 22.7 ± 0.4 m | 19.1 ± 0.1 mn | |

| K105 | 87.2 ± 0.6 a | 35.2 ± 0.2 f | 19.8 ± 0.1 n | 18.9 ± 0.1 no | |

| AY1 | 68.3 ± 0.4 e | 41.1 ± 0.2 e | 42.9 ± 5.6 h | 24.6 ± 0.2 k | |

| Variety | Crystallinity degree (%) | |

|---|---|---|

| Dry-milled | Wet-milled | |

| Rice Department 41 | 13.0 ± 0.1 i | 20.4 ± 0.4 e |

| Rice Department 45 | 13.9 ± 0.2 gh | 22.5 ± 0.1 c |

| Rice Department 47 | 13.3 ± 0.1 hi | 20.1 ± 0.2 e |

| Shaw Lung 97 | 13.7 ± 0.0 ghi | 23.4 ± 0.6 b |

| Prachin Buri 1 | 13.4 ± 0.0 hi | 20.6 ± 0.2 e |

| Prachin Buri 2 | 13.3 ± 0.3 hi | 23.3 ± 0.1 b |

| Plai Ngahm Prachin Buri | 14.7 ± 0.6 f | 22.5 ± 0.5 c |

| Khao Dawk Mali 105 | 14.2 ± 0.4 fg | 24.2 ± 0.1 a |

| Ayutthaya 1 | 13.4 ± 0.1 hi | 21.7 ± 0.0 d |

Table 2 Crystallinity characteristics of dry- and wet-milled rice flour.

| Variety | Crystallinity degree (%) | |

|---|---|---|

| Dry-milled | Wet-milled | |

| Rice Department 41 | 13.0 ± 0.1 i | 20.4 ± 0.4 e |

| Rice Department 45 | 13.9 ± 0.2 gh | 22.5 ± 0.1 c |

| Rice Department 47 | 13.3 ± 0.1 hi | 20.1 ± 0.2 e |

| Shaw Lung 97 | 13.7 ± 0.0 ghi | 23.4 ± 0.6 b |

| Prachin Buri 1 | 13.4 ± 0.0 hi | 20.6 ± 0.2 e |

| Prachin Buri 2 | 13.3 ± 0.3 hi | 23.3 ± 0.1 b |

| Plai Ngahm Prachin Buri | 14.7 ± 0.6 f | 22.5 ± 0.5 c |

| Khao Dawk Mali 105 | 14.2 ± 0.4 fg | 24.2 ± 0.1 a |

| Ayutthaya 1 | 13.4 ± 0.1 hi | 21.7 ± 0.0 d |

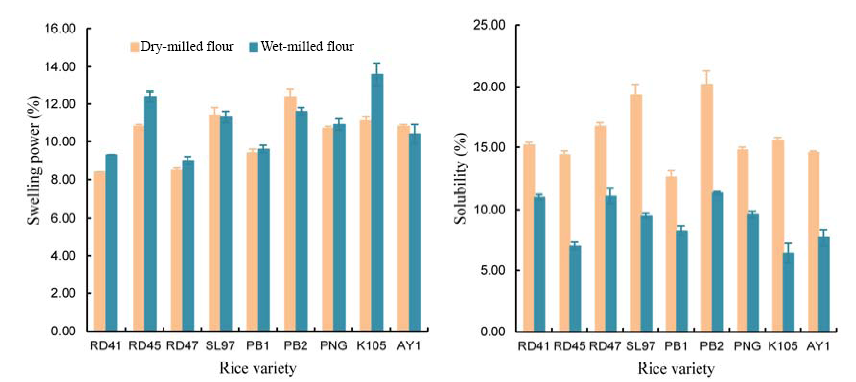

Fig. 6. Swelling power and solubility properties of rice flour at 90 °C. RD41, Rice Department 41; RD45, Rice Department 45; RD47, Rice Department 47; SL97, Shaw Lung 97; PB1, Prachin Buri 1; PB2, Prachin Buri 2; PNG, Plai Ngahm Prachin Buri; K105, Khao Dawk Mali 105; AY1, Ayutthaya 1.

| Variety | Treatment | Pasting temperature (°C) | Pasting viscosity (cP) | ||||

|---|---|---|---|---|---|---|---|

| Peak viscosity | Trough viscosity | Final viscosity | Breakdown | Setback | |||

| RD41 | Dry-milled | 87.2 ± 0.8 c | 1 235 ± 52 k | 875 ± 27 j | 1 901 ± 105 j | 360 ± 25 g | 1 026 ± 81 i |

| RD41 | Wet-milled | 91.1 ± 0.5 a | 2 298 ± 137 h | 1 680 ± 122 f | 3 287 ± 165 g | 621 ± 16 ef | 1 611 ± 68 de |

| RD45 | Dry-milled | 83.7 ± 0.5 e | 2 095 ± 105 i | 1 248 ± 68 h | 2 518 ± 82 hi | 847 ± 40 d | 1 270 ± 18 gh |

| RD45 | Wet-milled | 86.2 ± 0.6 cd | 3 467 ± 63 c | 1 932 ± 119 e | 3 198 ± 118 g | 1 536 ± 56 a | 1 266 ± 1 gh |

| RD47 | Dry-milled | 88.4 ± 0.4 b | 1 010 ± 64 l | 684 ± 62 k | 1 650 ± 65 k | 325 ± 5 g | 966 ± 19 i |

| RD47 | Wet-milled | 91.9 ± 0.4 a | 2 062 ± 61 i | 1 406 ± 53 g | 2 632 ± 56 h | 657 ± 15 e | 1 227 ± 27 h |

| SL97 | Dry-milled | 81.1 ± 0.4 f | 1 711 ± 123 j | 1 024 ± 70 i | 2 394 ± 139 i | 687 ± 53 e | 1 370 ± 72 g |

| SL97 | Wet-milled | 81.6 ± 0.1 f | 2 742 ± 42 e | 1 648 ± 36 f | 3 149 ± 45 g | 1 094 ± 39 b | 1 501 ± 40 ef |

| PB1 | Dry-milled | 84.3 ± 0.5 e | 2 624 ± 139 ef | 1 993 ± 100 de | 4 680 ± 222 b | 631 ± 40 ef | 2 687 ± 122 a |

| PB1 | Wet-milled | 91.3 ± 1.4 a | 3 818 ± 123 a | 2 892 ± 100 a | 4 615 ± 162 b | 926 ± 37 c | 1 723 ± 72 d |

| PB2 | Dry-milled | 78.3 ± 0.1 g | 2 003 ± 89 i | 1 005 ± 72 ij | 2 399 ± 87 i | 997 ± 32 c | 1 394 ± 25 fg |

| PB2 | Wet-milled | 80.8 ± 0.8 f | 3 183 ± 67 d | 2 083 ± 36 cd | 4 100 ± 61 d | 1 100 ± 82 b | 2 017 ± 64 c |

| PNG | Dry-milled | 78.9 ± 0.4 g | 2 569 ± 25 fg | 1 430 ± 33 g | 3 528 ± 21 f | 1 139 ± 13 b | 2 098 ± 21 c |

| PNG | Wet-milled | 83.8 ± 1.0 e | 3 740 ± 67 ab | 2 215 ± 116 c | 4 338 ± 82 c | 525 ± 105 a | 2 123 ± 82 c |

| K105 | Dry-milled | 86.2 ± 0.4 cd | 1 720 ± 78 j | 1 164 ± 82 h | 2 338 ± 99 i | 556 ± 50 f | 1 174 ± 19 h |

| K105 | Wet-milled | 76.2 ± 0.5 h | 3 235 ± 78 d | 1 696 ± 77 f | 2 532 ± 92 hi | 1 539 ± 33 a | 836 ± 53 j |

| AY1 | Dry-milled | 78.9 ± 0.6 g | 2 444 ± 144 gh | 1 482 ± 120 g | 3 871 ± 201 e | 962 ± 37 c | 2 389 ± 112 b |

| AY1 | Wet-milled | 85.7 ± 0.8 d | 3 626 ± 37 b | 2 677 ± 52 b | 4 960 ± 138 a | 949 ± 32 c | 2 283 ± 170 b |

Table 3 Pasting properties of dry-milled and wet-milled rice flour.

| Variety | Treatment | Pasting temperature (°C) | Pasting viscosity (cP) | ||||

|---|---|---|---|---|---|---|---|

| Peak viscosity | Trough viscosity | Final viscosity | Breakdown | Setback | |||

| RD41 | Dry-milled | 87.2 ± 0.8 c | 1 235 ± 52 k | 875 ± 27 j | 1 901 ± 105 j | 360 ± 25 g | 1 026 ± 81 i |

| RD41 | Wet-milled | 91.1 ± 0.5 a | 2 298 ± 137 h | 1 680 ± 122 f | 3 287 ± 165 g | 621 ± 16 ef | 1 611 ± 68 de |

| RD45 | Dry-milled | 83.7 ± 0.5 e | 2 095 ± 105 i | 1 248 ± 68 h | 2 518 ± 82 hi | 847 ± 40 d | 1 270 ± 18 gh |

| RD45 | Wet-milled | 86.2 ± 0.6 cd | 3 467 ± 63 c | 1 932 ± 119 e | 3 198 ± 118 g | 1 536 ± 56 a | 1 266 ± 1 gh |

| RD47 | Dry-milled | 88.4 ± 0.4 b | 1 010 ± 64 l | 684 ± 62 k | 1 650 ± 65 k | 325 ± 5 g | 966 ± 19 i |

| RD47 | Wet-milled | 91.9 ± 0.4 a | 2 062 ± 61 i | 1 406 ± 53 g | 2 632 ± 56 h | 657 ± 15 e | 1 227 ± 27 h |

| SL97 | Dry-milled | 81.1 ± 0.4 f | 1 711 ± 123 j | 1 024 ± 70 i | 2 394 ± 139 i | 687 ± 53 e | 1 370 ± 72 g |

| SL97 | Wet-milled | 81.6 ± 0.1 f | 2 742 ± 42 e | 1 648 ± 36 f | 3 149 ± 45 g | 1 094 ± 39 b | 1 501 ± 40 ef |

| PB1 | Dry-milled | 84.3 ± 0.5 e | 2 624 ± 139 ef | 1 993 ± 100 de | 4 680 ± 222 b | 631 ± 40 ef | 2 687 ± 122 a |

| PB1 | Wet-milled | 91.3 ± 1.4 a | 3 818 ± 123 a | 2 892 ± 100 a | 4 615 ± 162 b | 926 ± 37 c | 1 723 ± 72 d |

| PB2 | Dry-milled | 78.3 ± 0.1 g | 2 003 ± 89 i | 1 005 ± 72 ij | 2 399 ± 87 i | 997 ± 32 c | 1 394 ± 25 fg |

| PB2 | Wet-milled | 80.8 ± 0.8 f | 3 183 ± 67 d | 2 083 ± 36 cd | 4 100 ± 61 d | 1 100 ± 82 b | 2 017 ± 64 c |

| PNG | Dry-milled | 78.9 ± 0.4 g | 2 569 ± 25 fg | 1 430 ± 33 g | 3 528 ± 21 f | 1 139 ± 13 b | 2 098 ± 21 c |

| PNG | Wet-milled | 83.8 ± 1.0 e | 3 740 ± 67 ab | 2 215 ± 116 c | 4 338 ± 82 c | 525 ± 105 a | 2 123 ± 82 c |

| K105 | Dry-milled | 86.2 ± 0.4 cd | 1 720 ± 78 j | 1 164 ± 82 h | 2 338 ± 99 i | 556 ± 50 f | 1 174 ± 19 h |

| K105 | Wet-milled | 76.2 ± 0.5 h | 3 235 ± 78 d | 1 696 ± 77 f | 2 532 ± 92 hi | 1 539 ± 33 a | 836 ± 53 j |

| AY1 | Dry-milled | 78.9 ± 0.6 g | 2 444 ± 144 gh | 1 482 ± 120 g | 3 871 ± 201 e | 962 ± 37 c | 2 389 ± 112 b |

| AY1 | Wet-milled | 85.7 ± 0.8 d | 3 626 ± 37 b | 2 677 ± 52 b | 4 960 ± 138 a | 949 ± 32 c | 2 283 ± 170 b |

| Variety | To-Tc (°C) | ∆H (J/g) | ||

|---|---|---|---|---|

| Dry-milled | Wet-milled | Dry-milled | Wet-milled | |

| RD41 | 13.8 ± 0.2 ab | 11.2 ± 0.1 e | 5.2 ± 0.2 h | 9.6 ± 0.2 d |

| RD45 | 13.5 ± 0.5 b | 10.4 ± 0.2 f | 5.3 ± 0.2 d | 9.9 ± 0.2 cd |

| RD47 | 14.1 ± 0.2 a | 11.9 ± 0.1 d | 5.3 ± 0.3 h | 8.6 ± 0.3 e |

| SL97 | 10.2 ± 0.3 f | 8.3 ± 0.0 h | 4.2 ± 0.2 i | 11.4 ± 0.4 b |

| PB1 | 14.0 ± 0.0 a | 11.0 ± 0.1 e | 5.9 ± 0.0 g | 10.3 ± 0.3 c |

| PB2 | 10.5 ± 0.2 f | 8.4 ± 0.0 h | 3.3 ± 0.1 j | 12.1 ± 0.2 a |

| PNG | 9.3 ± 0.0 g | 9.0 ± 0.0 g | 5.1 ± 0.2 h | 11.2 ± 0.1 b |

| K105 | 12.7 ± 0.2 c | 11.4 ± 0.0 e | 3.9 ± 0.1 i | 11.5 ± 0.4 b |

| AY1 | 9.0 ± 0.2 g | 8.3 ± 0.1 h | 2.5 ± 0.0 k | 7.6 ± 0.3 f |

Table 4 Thermal properties of rice flours.

| Variety | To-Tc (°C) | ∆H (J/g) | ||

|---|---|---|---|---|

| Dry-milled | Wet-milled | Dry-milled | Wet-milled | |

| RD41 | 13.8 ± 0.2 ab | 11.2 ± 0.1 e | 5.2 ± 0.2 h | 9.6 ± 0.2 d |

| RD45 | 13.5 ± 0.5 b | 10.4 ± 0.2 f | 5.3 ± 0.2 d | 9.9 ± 0.2 cd |

| RD47 | 14.1 ± 0.2 a | 11.9 ± 0.1 d | 5.3 ± 0.3 h | 8.6 ± 0.3 e |

| SL97 | 10.2 ± 0.3 f | 8.3 ± 0.0 h | 4.2 ± 0.2 i | 11.4 ± 0.4 b |

| PB1 | 14.0 ± 0.0 a | 11.0 ± 0.1 e | 5.9 ± 0.0 g | 10.3 ± 0.3 c |

| PB2 | 10.5 ± 0.2 f | 8.4 ± 0.0 h | 3.3 ± 0.1 j | 12.1 ± 0.2 a |

| PNG | 9.3 ± 0.0 g | 9.0 ± 0.0 g | 5.1 ± 0.2 h | 11.2 ± 0.1 b |

| K105 | 12.7 ± 0.2 c | 11.4 ± 0.0 e | 3.9 ± 0.1 i | 11.5 ± 0.4 b |

| AY1 | 9.0 ± 0.2 g | 8.3 ± 0.1 h | 2.5 ± 0.0 k | 7.6 ± 0.3 f |

| 1 | AOAC.2005. Official Methods of Analysis of the Association of Official Analysis Chemists, 17th ed. Washington, USA: The Association. |

| 2 | Chen J J, Lu S, Lii C Y.1999. Effects of milling on the physicochemical characteristics of waxy rice in Taiwan.Cereal Chem, 76(5): 796-799. |

| 3 | Chen J J, Lii C Y, Lu S.2003. Physicochemical and morphological analyses on damaged rice starches.J Food Drug Anal, 11: 283-289. |

| 4 | BeMiller J N, Whisler R L. 2009. Starch: Chemistry and Technology. 3rd edn. New York, USA: Academic Press. |

| 5 | Haase N U, Mintus T, Detmold W.1995. Viscosity measurement of potato starch paste with Rapid Visco Analyzer.Starch/stärke, 47(4): 123-126. |

| 6 | Iturriaga L, Lopez B, Añon M.2004. Thermal and physicochemical characterization of seven argentine rice flours and starches.Food Res Int, 37(5): 439-447. |

| 7 | Joshi N D, Mohapatra D, Joshi D C.2013. Varietal selection of some indica rice for production of puffed rice.Food Bioproc Technol, 7: 299-305. |

| 8 | Juliano B O.1971. A simplified assay for milled rice amylose.Cereal Sci Today, 16: 334-360. |

| 9 | Kim Y S, Wiesenborn D P, Orr P H, Grant L A.1995. Screening potato starch for novel properties using differential scanning calorimetry.J Food Sci, 60(5): 1060-1065. |

| 10 | Lee Y E, Osman E M.1991. Correlation of morphological changes of rice starch granules with rheological properties during heating in excess water.J Kor Agric Chem Soc, 34(4): 379-385. |

| 11 | Li W H, Bai Y F, Mousaa-Saleh A S, Zhang Q, Shen Q.2011. Effect of high hydrostatic pressure on physicochemical and structural properties of rice starch.Food Bioproc Technol, 5(6): 2233-2241. |

| 12 | Marco C, Rosell C M.2008. Effect of different protein isolates and transglutaminase on rice flour properties.J Food Eng, 84(1): 132-139. |

| 13 | Medcalf D G, Gilles K A.1965. Wheat starches: I. Comparison of physicochemicals properties.Cereal Chem, 42: 558-568. |

| 14 | Montgomery D C.2005. Design and Analysis of Experiments. 6th ed. New Jersey, USA: John Wiley & Sons. |

| 15 | Park C S, Kang C S, Cheong Y K, Jung W, Woo S H.2010. Influence of puroindoline genotypes on grain characteristics, physico-chemical properties of flour and end-use quality of Korean wheats.Breeding Sci, 60: 233-242. |

| 16 | Patindol J, Wang Y J.2002. Fine structures of starches from long-grain rice cultivars with different functionality.Cereal Chem, 79(3): 465-469. |

| 17 | Schoch T J.1964. Swelling power and solubility of granular starches.Carbohydr Chem, 6: 106-108. |

| 18 | Singh N, Kaur L, Sandhu K S, Kaur J, Nishinari K.2006. Relationships between physicochemical, morphological, thermal, rheological properties of rice starches.Food Hydrocoll, 20(4): 532-542. |

| 19 | Suksomboon A, Naivikul O.2006. Effect of dry- and wet-milling processes on chemical, physicochemical properties and starch molecular structures of rice starches.Kasetsart J: Nat Sci, 40: 125-134. |

| 20 | Varavinit S, Shobsngob S, Varanyanond W, Chinachoti P, Naivikul O.2003. Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of Thai rice.Starch/stärke, 55: 410-415. |

| 21 | Xiang C, Ren J, Zhao X Q, Ding Z S, Zhang J, Wang C, Zhang J W, Joseph C A, Zhang Q, Pang Y L, Gao Y M, Shi Y Y.2015. Genetic dissection of low phosphorus tolerance related traits using selected introgression lines in rice.Rice Sci, 22(6): 264-274. |

| 22 | Yoenyongbuddhagal S, Noomhorm A.2002. Effect of physicochemical properties of high-amylose Thai rice flourson vermicelli quality.Cereal Chem, 79(4): 481-485. |

| 23 | Yu S F, Ma Y, Menager L, Sun D W.2010. Physicochemical properties of starch and flour from different rice cultivars.Food Bioproc Technol, 5(2): 626-637. |

| [1] | Chiara Fontanella Maria, Martin Maria, Tenni Daniele, Maria Beone Gian, Romani Marco. Effect of Milling and Parboiling Processes on Arsenic Species Distribution in Rice Grains [J]. Rice Science, 2021, 28(4): 402-408. |

| [2] | Shufen Chao, Yicong Cai, Baobing Feng, Guiai Jiao, Zhonghua Sheng, Ju Luo, Shaoqing Tang, Jianlong Wang, Peisong Hu, Xiangjin Wei. Editing of Rice Isoamylase Gene ISA1 Provides Insights into Its Function in Starch Formation [J]. Rice Science, 2019, 26(2): 77-87. |

| [3] | Yanjie Xu, Yining Ying, Shuhong Ouyang, Xiaoliang Duan, Hui Sun, Shukun Jiang, Shichen Sun, Jinsong Bao. Factors Affecting Sensory Quality of Cooked japonica Rice [J]. Rice Science, 2018, 25(6): 330-339. |

| [4] | Koteswara Reddy Chagam, Kimi Lalmuan, Haripriya Sundaramoorthy, Kang Nayoung. Effects of Polishing on Proximate Composition, Physico- Chemical Characteristics, Mineral Composition and Antioxidant Properties of Pigmented Rice [J]. Rice Science, 2017, 24(5): 241-252. |

| [5] | Daniel Abacar Jose, Zhao-miao Lin, Xin-cheng Zhang, Cheng-qiang Ding, She Tang, Zheng-hui Liu, Shao-hua Wang, Yan-feng Ding. Variation in Yield and Physicochemical Quality Traits among Mutants of Japonica Rice Cultivar Wuyujing 3 [J]. Rice Science, 2016, 23(1): 33-41. |

| [6] | J. Kale S., K. Jha S., K. Jha G., P. Sinha J., B. Lal S.. Soaking Induced Changes in Chemical Composition, Glycemic Index and Starch Characteristics of Basmati Rice [J]. Rice Science, 2015, 22(5): 227-236. |

| [7] | Swar Oo Kyaw, Kongjaimun Alisa, Khanthong Srisawat, Yi Myint, Tin Myint Tin, Korinsak Siriporn, Lanceras Siangliw Jonaliza, Myo Myint Khin, Vanavichit Apichart, Malumpong Chanate, Toojinda Theerayut. Characterization of Myanmar Paw San Hmwe Accessions Using Functional Genetic Markers [J]. Rice Science, 2015, 22(2): 53-64. |

| [8] | Abozar NASIRAHMADI, Bagher EMADI, Mohammad Hossein ABBASPOUR-FARD, Hamid AGHAGOLZADE. Influence of Moisture Content, Variety and Parboiling on Milling Quality of Rice Grains [J]. RICE SCIENCE, 2014, 21(2): 116-122. |

| [9] | LUO Li-li1, 2, #, ZHANG Ying-xin1, #, CHEN Dai-bo1, ZHAN Xiao-deng1, SHEN Xi-hong1, CHENG Shi-hua1, CAO Li-yong1. QTL Mapping for Hull Thickness and Related Traits in Hybrid Rice Xieyou 9308 [J]. RICE SCIENCE, 2014, 21(1): 29-38. |

| [10] | Seila SAR, Morgan J. TIZZOTTI, Jovin HASJIM, Robert G. GILBERT. Effects of Rice Variety and Growth Location in Cambodia on Grain Composition and Starch Structure [J]. RICE SCIENCE, 2014, 21(1): 47-58. |

| [11] | P. SUREKHA RAO1, B. MISHRA1, S. R. GUPTA2. Effect of Soil Salinity and Alkalinity on Grain Quality of Tolerant, Semi-Tolerant and Sensitive Rice Genotypes [J]. RICE SCIENCE, 2013, 20(4): 284-291. |

| [12] | N. VENKATACHALAPATHY1, R. UDHAYAKUMAR2. Effects of Continuous Steaming on Milling Characteristics of Two Indica Rice Varieties [J]. RICE SCIENCE, 2013, 20(4): 309-312. |

| [13] | Subajiny VELUPPILLAI, Ketheeswary NITHYANANTHARAJAH, Seevaratnam VASANTHARUBA, Sandrasegarampillai BALAKUMAR, Vasanthy ARASARATNAM. Optimization of Bread Preparation from Wheat Flour and Malted Rice Flour [J]. RICE SCIENCE, 2010, 17(1): 51-59 . |

| [14] | CHEN Tao, ZHANG Ya-dong, ZHAO Ling, ZHU Zhen, LIN Jing, ZHANG Suo-bing, WANG Cai-lin. A Cleaved Amplified Polymorphic Sequence Marker to Detect Variation in Wx Locus Conditioning Translucent Endosperm in Rice [J]. RICE SCIENCE, 2009, 16(2): 106-110 . |

| [15] | HAO Hu-lin, WEI You-zhang, YANG Xiao-e, FENG Ying, WU Chun-yong. Effects of Different Nitrogen Fertilizer Levels on Fe, Mn, Cu and Zn Concentrations in Shoot and Grain Quality in Rice (Oryza sativa) [J]. RICE SCIENCE, 2007, 14(4): 289-294 . |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||