Rice Science ›› 2022, Vol. 29 ›› Issue (1): 16-30.DOI: 10.1016/j.rsci.2021.12.002

• Review • Previous Articles Next Articles

Amanda Müller1, Marcela Trojahn Nunes1, Vanessa Maldaner1, Paulo Carteri Coradi1,2( ), Rosana Santos de Moraes1, Samuel Martens1, Andressa Fernandes Leal1, Vladison Fogliato Pereira1, Cristielle König Marin1

), Rosana Santos de Moraes1, Samuel Martens1, Andressa Fernandes Leal1, Vladison Fogliato Pereira1, Cristielle König Marin1

Received:2021-02-18

Accepted:2021-07-15

Online:2022-01-28

Published:2022-01-01

Contact:

Paulo Carteri Coradi

Amanda Müller, Marcela Trojahn Nunes, Vanessa Maldaner, Paulo Carteri Coradi, Rosana Santos de Moraes, Samuel Martens, Andressa Fernandes Leal, Vladison Fogliato Pereira, Cristielle König Marin. Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality[J]. Rice Science, 2022, 29(1): 16-30.

Add to citation manager EndNote|Ris|BibTeX

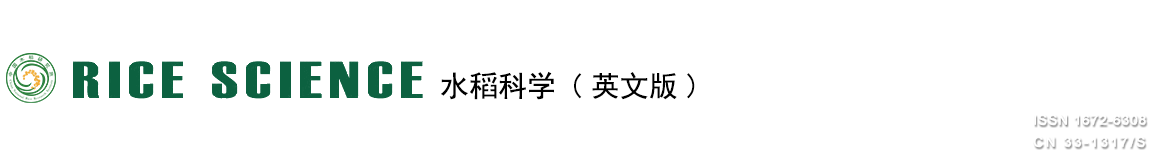

Fig. 2. Drying process in rice grains. A , Start drying in rice plant. B, Need to immediately subject the rice grains to drying. C, Intermittent dryer. The intermittent dryer consists of two chambers, one for drying and the other for equalization. D, Procedure in the equalization chamber. E, Procedure in the drying chamber. Pg, Grain vapor pressure; Par, Air vapor pressure; T1, Exhaust air temperature; T2, Inlet air temperature; UR1, Exhaust air relative humidity; UR2, Inlet air relative humidity.

| Purpose | Equation | Model |

|---|---|---|

| Description of drying rice grains | MR = exp(-kt) | Newton |

| MR = exp(-ktn) | Page | |

| MR = a exp(-kt) | Henderson and Pabis | |

| MR = a exp(-kt) + c | Logarithmic | |

| MR = a exp(-k0t) + b exp(-k1t) | Two terms | |

| MR = 1 + at +btz | Wang and Singh | |

| MR = a exp(-kt) + b exp(-k0t) + c exp(-k1t) | Henderson and Pabis modified | |

| MR = a exp(-ktn) + b t | Midilli | |

| MR = a exp(-kt) + (1 - a) exp(-kbt) | Diffusion approximation | |

| MR = a exp(-kt) + (1 - a) exp(-kat) | Exponential of two terms | |

| MR = a exp(-kt) + (1 - a) exp(-k1t) | Verna | |

| MR = a0 / a exp(kt) | Logistic | |

| Determining equilibrium moisture content | | Oswin |

| | Henderson | |

| | Henderson modified | |

| | Chung-Pfost | |

| Xe = exp(a + bT) [-ln(RH)]-2/c | Halsey | |

| Xe = X × c / [(1 - a)(1 + c - a)] | BET | |

| Xe = K·ab / Tc | Sabbah |

Table 1. Equations for description of drying rice grains and determining equilibrium moisture content.

| Purpose | Equation | Model |

|---|---|---|

| Description of drying rice grains | MR = exp(-kt) | Newton |

| MR = exp(-ktn) | Page | |

| MR = a exp(-kt) | Henderson and Pabis | |

| MR = a exp(-kt) + c | Logarithmic | |

| MR = a exp(-k0t) + b exp(-k1t) | Two terms | |

| MR = 1 + at +btz | Wang and Singh | |

| MR = a exp(-kt) + b exp(-k0t) + c exp(-k1t) | Henderson and Pabis modified | |

| MR = a exp(-ktn) + b t | Midilli | |

| MR = a exp(-kt) + (1 - a) exp(-kbt) | Diffusion approximation | |

| MR = a exp(-kt) + (1 - a) exp(-kat) | Exponential of two terms | |

| MR = a exp(-kt) + (1 - a) exp(-k1t) | Verna | |

| MR = a0 / a exp(kt) | Logistic | |

| Determining equilibrium moisture content | | Oswin |

| | Henderson | |

| | Henderson modified | |

| | Chung-Pfost | |

| Xe = exp(a + bT) [-ln(RH)]-2/c | Halsey | |

| Xe = X × c / [(1 - a)(1 + c - a)] | BET | |

| Xe = K·ab / Tc | Sabbah |

| Storage material | Storage temperature (ºC) | Storage period (Month) | Rice type | Result | Reference |

|---|---|---|---|---|---|

| Glass bottle (airtight) | 4 | 12 | Polished rice | Absence of organized crystalline structure, resulting in lower breaking temperature for starch gelatinization | Zhou et al, |

| 37 | 12 | Polished rice | Aging process made the crystalline structure more organized, resulting in an elevation of the rupture temperature for starch gelatinization | ||

| Transparent nylon packaging | 28-35 | 12 | Polished red organic rice | Impacted the physicochemical quality of the grains, providing more accentuated aging, resulting in harder grains and less sticky texture | Tananuwong and Malila, |

| Polyethylene packaging | 0-40 | 4 | Paddy rice | Reduction in white color of grains and whiteness | Sung et al, |

| Low density polyethylene packaging (semi-hermetic) | 16 and 24 | 12 | Brown rice | Maintenance of percentage of carbohydrates and other nutrients (protein, lipids and ash); Significant increase in water content | Ziegler et al, |

| 32 | 12 | Brown rice | Maintenance of the initial water content, percentage of carbohydrates and other nutrients (protein, lipids and ash) | ||

| 40 | 12 | Brown rice | Significant increase in carbohydrate content (1.4% more); Maintenance of protein, lipids and ash; Significant reduction in water content (1.0%) | ||

| Transparent nylon packaging | 30 | 1 | Polished rice | Water content reduction from 14.0% to 9.2%. Protein and lipid content remained stable; Higher percentage of whiteness | Ahmad et al, |

| 45 | 1 | Polished rice | Water content reduction from 14.0% to 4.0%; Protein content remains stable; Reduction in lipid content; More transparent grains | ||

| 60 | 1 | Polished rice | Water content reduction from 14.0% to 1.7%; Slight reduction of protein levels; Reduction in lipid content; More transparent grains | ||

| Polyethylene packaging (simulation chamber) | 30 and 35 | 3 | Polished rice | Increased water content of grains and transparency level, but reduced growth of fungi on the rice surface | An et al, |

| 20 | 3 | Polished rice | Slow reduction of water content of the grains; Emergence of yellowish grains due to lipid oxidation | ||

| Sealed glass tank | 10, 15, 20 and 27 | 4 | Paddy rice | Changes in the color of the grains, the storage time and temperature did not directly influence, the development of microorganisms responsible for the modifications | Shafiekhani et al, |

| 40 | 4 | Paddy rice | Significant change in grain color, with a marked change in the last week; Temperature and storage time did not influence the change, but the development of microorganisms | ||

| PPWoven packaging | 18.6 | 8 | Polished rice | Low yield and high percentage of broken grains after drying at 55 ºC- 65 ºC, generating an impact on quality due to the appearance of cracks; Drying with temperatures below 55 ºC showed better yield and reduced number of broken grains; Changes in chemical composition of grains were not attributed to storage time and temperature | Scariot et al, |

| Aluminum laminated polyethylene packaging (vacuum) | 4 | 6 | Parboiled germinated rice (PGR) | 0.16% increase in water content; Water activity remained stable | Klaykruayat et al, |

| 30 | 6 | PGR | Significant reduction (2.67%) in water content, resulting in a decrease in water activity | ||

| Polyamide-polyethylene packaging (vacuum) | 4 | 6 | PGR | Maintenance of water content; Slight reduction in water activity | Klaykruayat et al, |

| 30 | 6 | PGR | Slight reduction in water content and water activity |

Table 2. Influence of storage temperature over time on physical-chemical quality and color of rice grains.

| Storage material | Storage temperature (ºC) | Storage period (Month) | Rice type | Result | Reference |

|---|---|---|---|---|---|

| Glass bottle (airtight) | 4 | 12 | Polished rice | Absence of organized crystalline structure, resulting in lower breaking temperature for starch gelatinization | Zhou et al, |

| 37 | 12 | Polished rice | Aging process made the crystalline structure more organized, resulting in an elevation of the rupture temperature for starch gelatinization | ||

| Transparent nylon packaging | 28-35 | 12 | Polished red organic rice | Impacted the physicochemical quality of the grains, providing more accentuated aging, resulting in harder grains and less sticky texture | Tananuwong and Malila, |

| Polyethylene packaging | 0-40 | 4 | Paddy rice | Reduction in white color of grains and whiteness | Sung et al, |

| Low density polyethylene packaging (semi-hermetic) | 16 and 24 | 12 | Brown rice | Maintenance of percentage of carbohydrates and other nutrients (protein, lipids and ash); Significant increase in water content | Ziegler et al, |

| 32 | 12 | Brown rice | Maintenance of the initial water content, percentage of carbohydrates and other nutrients (protein, lipids and ash) | ||

| 40 | 12 | Brown rice | Significant increase in carbohydrate content (1.4% more); Maintenance of protein, lipids and ash; Significant reduction in water content (1.0%) | ||

| Transparent nylon packaging | 30 | 1 | Polished rice | Water content reduction from 14.0% to 9.2%. Protein and lipid content remained stable; Higher percentage of whiteness | Ahmad et al, |

| 45 | 1 | Polished rice | Water content reduction from 14.0% to 4.0%; Protein content remains stable; Reduction in lipid content; More transparent grains | ||

| 60 | 1 | Polished rice | Water content reduction from 14.0% to 1.7%; Slight reduction of protein levels; Reduction in lipid content; More transparent grains | ||

| Polyethylene packaging (simulation chamber) | 30 and 35 | 3 | Polished rice | Increased water content of grains and transparency level, but reduced growth of fungi on the rice surface | An et al, |

| 20 | 3 | Polished rice | Slow reduction of water content of the grains; Emergence of yellowish grains due to lipid oxidation | ||

| Sealed glass tank | 10, 15, 20 and 27 | 4 | Paddy rice | Changes in the color of the grains, the storage time and temperature did not directly influence, the development of microorganisms responsible for the modifications | Shafiekhani et al, |

| 40 | 4 | Paddy rice | Significant change in grain color, with a marked change in the last week; Temperature and storage time did not influence the change, but the development of microorganisms | ||

| PPWoven packaging | 18.6 | 8 | Polished rice | Low yield and high percentage of broken grains after drying at 55 ºC- 65 ºC, generating an impact on quality due to the appearance of cracks; Drying with temperatures below 55 ºC showed better yield and reduced number of broken grains; Changes in chemical composition of grains were not attributed to storage time and temperature | Scariot et al, |

| Aluminum laminated polyethylene packaging (vacuum) | 4 | 6 | Parboiled germinated rice (PGR) | 0.16% increase in water content; Water activity remained stable | Klaykruayat et al, |

| 30 | 6 | PGR | Significant reduction (2.67%) in water content, resulting in a decrease in water activity | ||

| Polyamide-polyethylene packaging (vacuum) | 4 | 6 | PGR | Maintenance of water content; Slight reduction in water activity | Klaykruayat et al, |

| 30 | 6 | PGR | Slight reduction in water content and water activity |

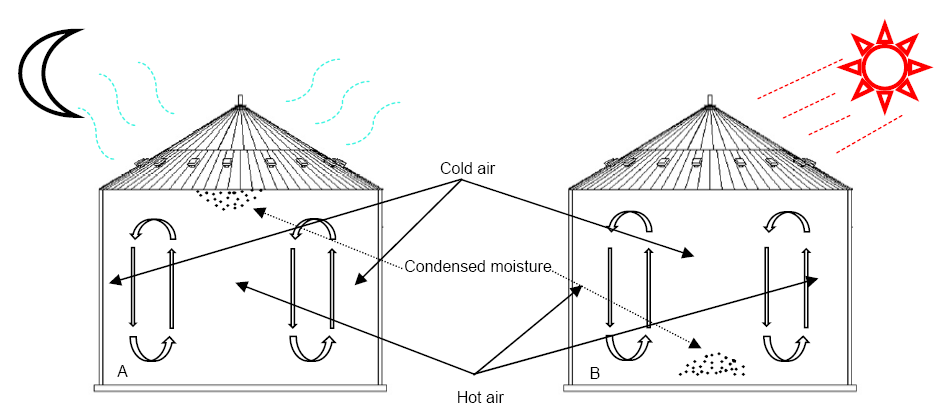

Fig. 4. Heat and water transfers and convective currents and in metallic silos. A , Moisture condensation on top in the night. B, Moisture condensation at the bottom in the daytime.

| [1] | Abalone R, Gáston A, Bartosik R, Cardoso L, Rodríguez J. 2011. Gas concentration in the interstitial atmosphere of a wheat silo-bag. Part II: Model sensitivity and effect of grain storage conditions. J Stored Prod Res, 47(4): 276-283. |

| [2] | Ahmad U, Alfaro L, Yeboah-Awudzi M, Kyereh E, Dzandu B, Bonilla F, Chouljenko A, Sathivel S. 2017. Influence of milling intensity and storage temperature on the quality of Catahoula rice (Oryza sativa L.). LWT, 75: 386-392. |

| [3] | An Y X, Zhou X Q, Zhang Y R. 2018. Changes in physicochemical, cooking and sensory characteristics of rice shifted from low- temperature storage. Grain Oil Sci Technol, 1(1): 8-14. |

| [4] | Aquerreta J, Iguaz A, Arroqui C, Vírseda P. 2007. Effect of high temperature intermittent drying and tempering on rough rice quality. J Food Eng, 80(2): 611-618. |

| [5] | Atungulu G G, Pan Z L. 2014. Rice industrial processing worldwide and impact on macro- and micronutrient content, stability, and retention. Ann N Y Acad Sci, 1324(1): 15-28. |

| [6] | Baldin T, Marchiori J N C, dos Santos G A, Gallo R, dos Santos O, Valente B M R T, Hein P R G. . 2018. Evaluation of alternative sample preparation methods for development of NIR models to assess chemical properties of wood. BioResources, 13(3): 5394-5407. |

| [7] | Bao J S. 2019. Postharvest technology: Rice storage and cooling conservation. In: Atungulu G G, Kolb R E, Karcher J, Shad Z M. Rice: Chemistry and Technology. 4th edn. St. Paul, USA: American Association of Cereal Chemists Press, : 517-555. |

| [8] | Barnaby J Y, Rohila J S, Henry C G, Sicher R C, Reddy V R, McClung A M. 2019. Physiological and metabolic responses of rice to reduced soil moisture: Relationship of water stress tolerance and grain production. Int J Mol Sci, 20(8): 1846. |

| [9] | Barreto A A, Abalone R, Gastón A, Ochandio D, Cardoso L, Bartosik R. 2017. Validation of a heat, moisture and gas concentration transfer model for soybean (Glycine max) grains stored in plastic bags (silo bags). Biosyst Eng, 158: 23-37. |

| [10] | Bazoni C H V, Ida E I, Barbin D F, Kurozawa L E. 2017. Near-infrared spectroscopy as a rapid method for evaluation physicochemical changes of stored soybeans. J Stored Prod Res, 73: 1-6. |

| [11] | Bello M O, Tolaba M P, Suarez C. 2007. Water absorption and starch gelatinization in whole rice grain during soaking. LWT Food Sci Technol, 40(2): 313-318. |

| [12] | Bernaola L, Cange G, Way M O, Gore J, Hardke J, Stout M. 2018. Natural colonization of rice by arbuscular mycorrhizal fungi in different production areas. Rice Sci, 25(3): 169-174. |

| [13] | Binelo M O, Faoro V, Kathatourian O A, Ziganshin B. 2019. Airflow simulation and inlet pressure profile optimization of a grain storage bin aeration system. Comput Electron Agric, 164: 104923. |

| [14] | Buggenhout J, Brijs K, Celus I, Delcour J A. 2013. The breakage susceptibility of raw and parboiled rice: A review. J Food Eng, 117(3): 304-315. |

| [15] | Chen X, Qian P, Zhang X J, Liu F N, Lu R R. 2014. Improving instant rice quality by novel combined drying. Drying Technol, 32(12): 1448-1456. |

| [16] | Coradi P C, Fernandes C H P, Helmich J C. 2016. Adjustment of mathematical models and quality of soybean grains in the drying with high temperatures. Rev Bras Eng Agric Amb, 20(4): 385-392. |

| [17] | Coradi P C, Lemes A F C, Steinhaus J I, Müller A, Alves C Z. 2018. Mathematical modeling of drying in a new concept of silo-dryer-aerator and the quality of soybean seeds (Glycine max (L.) Merrill). J Agric Sci Technol B, 8: 483-498. |

| [18] | Coradi P C, Lemes  F C. 2019. Experimental prototype of silo-dryer-aerator of grains using computational fluid dynamics (CFD) system. Acta Sci Technol, 41(1): e36949. |

| [19] | Coradi P C, Müller A, Souza G A C, Steinhaus J I, Wagner R. 2020a. Quality of soybean cultivars in the drying and storage processes in real scale and experimental. J Food Process Eng, 43: e13418. |

| [20] | Coradi P C, Nunes M T, Dutra A P, de Souza G A C, Carneiro L O, Steinhaus J I. 2020b. Evaluation of the operating system of a storage unit for drying silos and the quality of rice grains. Res Soc Dev, 9(9): e235997073. |

| [21] | Coradi P C, Padia C L, Jaques L B A, de Souza G A C, Lima R E, Müller A, Teodoro P E, Steinhaus J I, Carneiro L O. 2020c. Adaptation of technological packaging for conservation of soybean seeds in storage units as an alternative to modified atmospheres. PLoS One, 15(11): e0241787. |

| [22] | Coradi P C, Lemes A F C, Müller A, Jaques I T P, Dubal L B A, dos Santos Bilhalva N, Teodoro P E, Steinhaus J I, Maier D E. 2021. Silo-dryer-aerator in fixed and thick layer conceptualized for high quality of grains applied in different social scales post-harvest: Modeling and validation. Drying Technol, 1: 1-26. |

| [23] | de Guzman C, Esguerra M, Linscombe S, Berger G, Sha X Y, Oard J. 2017. Genetic analysis of photoperiod/thermosensitive male sterility in rice under US environments. Crop Sci, 57(4): 1957-1965. |

| [24] | de Medeiros A D, da Silva L J, da Silva J M, dos Santos Dias D C F, Pereira M D. 2020. IJCropSeed: An open-access tool for high-throughput analysis of crop seed radiographs. Comput Eletron Agric, 175: 105555. |

| [25] | de Menezes N L, Pasqualli L L, Barbieri A P P, Vidal M D, Conceição G M. 2012. Drying temperatures on physical integrity, physiological quality and chemical composition of rice seeds. Pesquis Agropec Trop, 42(4): 430-436. |

| [26] | Demont M, Zossou E, Rutsaert P, Ndour M, van Mele P, Verbeke W. 2012. Consumer valuation of improved rice parboiling technologies in Benin. Food Qual Pref, 23(1): 63-70. |

| [27] | Ding C, Khir R, Pan Z L, Wood D F, Venkitasamy C, Tu K, El-Mashad H, Berrios J. 2018. Influence of infrared drying on storage characteristics of brown rice. Food Chem, 264: 149-156. |

| [28] | Donlao N, Ogawa Y. 2017. Impact of postharvest drying conditions on in vitro starch digestibility and estimated glycemic index of cooked non-waxy long-grain rice (Oryza sativa L.). J Sci Food Agric, 97(3): 896-901. |

| [29] | Donlao N, Ogawa Y. 2018. Impacts of processing conditions on digestive recovery of polyphenolic compounds and stability of the antioxidant activity of green tea infusion during in vitro gastrointestinal digestion. LWT, 89: 648-656. |

| [30] | Donlao N, Matsushita Y, Ogawa Y. 2018. Influence of postharvest drying conditions on resistant starch content and quality of non-waxy long-grain rice(Oryza sativa L.). Drying Technol, 36(8): 952-964. |

| [31] | Elert E. 2014. Rice by the numbers: A good grain. Nature, 514: S50-S51. |

| [32] | Elias M C, Lopes V, Gutkoski L C, Oliveira M, Mazzutt S, Dias A R G. 2007. Grain pre-storage, storage and conservation operations. In: Elias M C, Oliveira M, Elias S A A, Dias A R G, Antunes P L. Post-harvest Rice: Drying, Storage and QualityPelotas: Edgraf UFPel: 147-244. |

| [33] | Faoro V, Khatchatourian O A, Binelo M O. 2018. Airflow performance analysis in bulk warehouses. Proc Ser Braz Soc Appl Comput Math, 6(1): 0100221-0100222. |

| [34] | Fryer M S, Slaton N A, Roberts T L, Hardke J T, Norman R J. 2019. Validation of soil-test-based phosphorus and potassium fertilizer recommendations for flood-irrigated rice. Agron J, 111(5): 2523-2535. |

| [35] | Gomes Junior F G. 2010. Application of image analysis to evaluate internal seed morphology. Inf Abrates, 20(3): 33-50. |

| [36] | Gong E S, Luo S J, Li T, Liu C M, Zhang G W, Chen J, Zeng Z C, Liu R H. 2017. Phytochemical profiles and antioxidant activity of processed brown rice products. Food Chem, 232: 67-78. |

| [37] | Heinemann R J B, Fagundes P L, Pinto E A, Penteado M V C, Lanfer-Marquez U M. 2005. Comparative study of nutrient composition of commercial brown, parboiled and milled rice from Brazil. J Food Compos Anal, 18(4): 287-296. |

| [38] | Hidalgo R, Pozzolo O, Domínguez F, Serafini E, Botta G. 2013. Studies of different factors affecting the quality of rice preserved in plastic bags. Rev Agrotec, 20: 23-29. |

| [39] | Huang H B, Danao M G C, Rausch K D, Singh V. 2013. Diffusion and production of carbon dioxide in bulk corn at various temperatures and moisture contents. J Stored Prod Res, 55: 21-26. |

| [40] | Inprasit C, Noomhorm A. 2001. Effect of drying air temperature and grain temperature of different types of dryer and operation on rice quality. Drying Technol, 19(2): 389-404. |

| [41] | Junka N, Wongs-Aree C, Rattanamechaiskul C. 2018. Optimal drying and storage conditions for purple rice based on expected high quality. J Food Process Preserv, 42(2): e13502. |

| [42] | Kale S J, Jha S K, Jha G K, Sinha J P, Lal S B. 2015. Soaking induced changes in chemical composition, glycemic index and starch characteristics of basmati rice. Rice Sci, 22(5): 227-236. |

| [43] | Kaur A, Bhise S, Kaur M. 2020. Hydrothermal treatments for paddy to improve physicochemical quality of brown rice. J Microbiol Biotechnol Food Sci, 9(5): 913-926. |

| [44] | Khatchatourian O A, Binelo M O, Faoro V, Toniazzo N A. 2016. Three-dimensional simulation and performance evaluation of air distribution in horizontal storage bins. Biosyst Eng, 142: 42-52. |

| [45] | Khatchatourian O A, Binelo M O, Neutzling R, Faoro V. 2017. Models to predict the thermal state of rice stored in aerated vertical silos. Biosyst Eng, 161: 14-23. |

| [46] |

Kingman D M, Field W E. 2005. Using fault tree analysis to identify contributing factors to engulfment in flowing grain in on-farm grain bins. J Agric Saf Health, 11(4): 395-405.

PMID |

| [47] | Klaykruayat S, Mahayothee B, Khuwijitjaru P, Nagle M, Müller J. 2020. Influence of packaging materials, oxygen and storage temperature on quality of germinated parboiled rice. LWT, 121: 108926. |

| [48] |

Köckenberger W. 2001. Functional imaging of plants by magnetic resonance experiments. Trends Plant Sci, 6(7): 286-292.

PMID |

| [49] | Kudra T. 1996. On-farm drying and storage systems. Drying Technol, 14(2): 477-478. |

| [50] | Kumar D, Kalita P. 2017. Reducing postharvest losses during storage of grain crops to strengthen food security in developing countries. Foods, 6(1): 8. |

| [51] | Kumar P A, Bal S. 2007. Automatic unhulled rice grain crack detection by X-ray imaging. Trans ASABE, 50(5): 1907-1911. |

| [52] | Kuo T Y, Chung C L, Chen S Y, Lin H A, Kuo Y F. 2016. Identifying rice grains using image analysis and sparse-representation-based classification. Comput Electron Agric, 127: 716-725. |

| [53] | Lang G H, Lindemann I S, Ferreira C D, Hoffmann J F, Vanier N L, de Oliveira M. 2019. Effects of drying temperature and long-term storage conditions on black rice phenolic compounds. Food Chem, 287: 197-204. |

| [54] | Lang G H, Lindemann I S, Goebel J T, Ferreira C D, Acunha T S, de Oliveira M. 2020. Fluidized-bed drying of black rice grains: Impact on cooking properties, in vitro starch digestibility, and bioaccessibility of phenolic compounds. J Food Sci, 85(6): 1717-1724. |

| [55] | Leethanapanich K, Mauromoustakos A, Wang Y J. 2016. Impacts of parboiling conditions on quality characteristics of parboiled commingled rice. J Cereal Sci, 69: 283-289. |

| [56] | Li Z Y, Wang R F, Kudra T. 2011. Uniformity issue in microwave drying. Drying Technol, 29(6): 652-660. |

| [57] | Lurstwut B, Pornpanomchai C. 2017. Image analysis based on color, shape and texture for rice seed (Oryza sativa L.) germination evaluation. Agric Nat Res, 51(5): 383-389. |

| [58] | Müller A, Coradi P C, Steinhaus J I, de Souza G A C, Carneiro L O, Jaques L B A, Grohs M. 2020. Physical quality of grains benefited from rice cultivars produced at different levels of fertilization. Cienc Nat, 42: e29. |

| [59] | Mussi L P, Guimarães A O, Ferreira K S, Pereira N R. 2015. Spouted bed drying of jambolão (Syzygium cumini) residue: Drying kinetics and effect on the antioxidant activity, anthocyanins and nutrients contents. LWT Food Sci Technol, 61(1): 80-88. |

| [60] | Mutungi C, Muthoni F, Bekunda M, Gaspar A, Kabula E, Abass A. 2019. Physical quality of maize grain harvested and stored by smallholder farmers in the northern highlands of Tanzania: Effects of harvesting and pre-storage handling practices in two marginally contrasting agro-locations. J Stored Prod Res, 84: 101517. |

| [61] | Nasirahmadi A, Emadi B, Abbaspour-fard M H, Aghagolzade H. 2014. Influence of moisture content, variety and parboiling on milling quality of rice grains. Rice Sci, 21(2): 116-122. |

| [62] | Neto A J S, de Carvalho D. 2015. Thermistor based system for grain aeration monitoring and control. Comput Electron Agric, 116: 45-54. |

| [63] | Norkaew O, Boontakham P, Dumri K, Noenplab A N L, Sookwong P, Mahatheeranont S. 2017. Effect of post-harvest treatment on bioactive phytochemicals of Thai black rice. Food Chem, 217: 98-105. |

| [64] | Norton T, Sun D W. 2008. Recent advances in the use of high pressure as an effective processing technique in the food industry. Food Bioprocess Technol, 1: 2-34. |

| [65] | Olatunde G A, Atungulu G G. 2017. Potential of turbulence interference in rough rice bin drying and storage systems fitted with cabling technology. Biosyst Eng, 163: 1-14. |

| [66] | Oli P, Ward R, Adhikari B, Torley P. 2014. Parboiled rice: Understanding from a materials science approach. J Food Eng, 124(9): 173-183. |

| [67] | Olorunfemi B J, Kayode S E. 2021. Post-harvest loss and grain storage technology: A review. Turk J Agric Food Sci Technol, 9(1): 75-83. |

| [68] | Oyoh K B, Menkiti M C. 2013. Optimum safe drying temperature for seed grains. Agric J, 3(3): 190-192. |

| [69] | Parnsakhorn S, Langkapin J. 2018. Effects of drying temperatures on physicochemical properties of germinated brown rice. Songkl J Sci Technol, 40(1): 127-134. |

| [70] | Patindol J, Wang Y J, Jane J I. 2003. Structure functionality changes in starch following rough rice storage. Starch/Stärke, 57(5): 197-207. |

| [71] |

Ramaswamy S K, Mosher G A. 2017. Using workers’ compensation claims data to characterize occupational injuries in the commercial grain elevator industry. J Agric Saf Health, 23(3): 203-217.

PMID |

| [72] | Ramos A H, Rockenbach B A, Ferreira C D, Gutkoski L C, de Oliveira M. 2019. Characteristics of flour and starch isolated from red rice subjected to different drying conditions. Starch/Stärke, 71: 1800257. |

| [73] | Rattanamechaiskul C, Junka N, Wongs-Aree C, Prachayawarakorn S, Soponronnarit S. 2016. Influence of hot air fluidized bed drying on quality changes of purple rice. Drying Technol, 34(12): 1462-1470. |

| [74] | Rodríguez-Arzuaga M, Cho S, Billiris M A, Siebenmorgen T, Seo H S. 2016. Impacts of degree of milling on the appearance and aroma characteristics of raw rice. J Sci Food Agric, 96(9): 3017-3022. |

| [75] | Rodriguez-Zamora M G, Medina-Escobar L, Mora G, Zock J P, de Joode B V W, Mora A M. 2017. Dust exposure in workers from grain storage facilities in Costa Rica. Int J Hyg Environ Health, 220(6): 1039-1045. |

| [76] | Runge J, Heringer O A, Ribeiro J S, Biazati L B. 2019. Multi-element rice grains analysis by ICP OES and classification by processing types. Food Chem, 271: 419-424. |

| [77] | Sarangapani C, Thirumdas R, Devi Y, Trimukhe A, Deshmukh R R, Annapure U S. 2016. Effect of low-pressure plasma on physico-chemical and functional properties of parboiled rice flour. LWT Food Sci Technol, 69(2): 482-489. |

| [78] | Scariot M A, Karlinski L, Dionello R G, Radünz A L, Radünz L L. 2020. Effect of drying air temperature and storage on industrial and chemical quality of rice grains. J Stored Prod Res, 89: 101717. |

| [79] | Selman J, Spickett J, Jansz J, Mullins B. 2019. Confined space rescue: A proposed procedure to reduce the risks. Saf Sci, 113: 78-90. |

| [80] | Shad Z M, Atungulu G G. 2019. Post-harvest kernel discoloration and fungi activity in long-grain hybrid, pureline and medium- grain rice cultivars as influenced by storage environment and antifungal treatment. J Stored Prod Res, 81: 91-99. |

| [81] | Shafiekhani S, Wilson S A, Atungulu G G. 2018. Impacts of storage temperature and rice moisture content on color characteristics of rice from fields with different disease management practices. J Stored Prod Res, 78: 89-97. |

| [82] | Siebenmorgen T J, Bautista R C, Counce P A. 2007. Optimal harvest moisture contents for maximizing milling quality of long- and medium-grain rice cultivars. Appl Eng Agric, 23(4): 517-527. |

| [83] | Silva J S. 2008. Drying and storage of agricultural products. Viçosa: Aprenda Fácil, (2): 560. |

| [84] | Singh C B, Fielke J M. 2017. Recent developments in stored grain sensors, monitoring and management technology. IEEE Instrum Meas Mag, 20(3): 32-55. |

| [85] | Singh N, Kaur L, Sandhu K S, Kaur J, Nishinari K. 2006. Relationships between physicochemical, morphological, thermal, rheological properties of rice starches. Food Hydrocoll, 20(4): 532-542. |

| [86] | Sodhi N S, Singh N, Arora M, Singh J. 2003. Changes in physico-chemical, thermal, cooking and textural properties of rice during aging. J Food Process Preserv, 27(5): 387-400. |

| [87] | Srisang N, Varanyanond W, Soponronnarit S, Prachayawarakorn S. 2011. Effects of heating media and operating conditions on drying kinetics and quality of germinated brown rice. J Food Eng, 107: 385-392. |

| [88] | Sung J, Kim B K, Kim B S, Kim Y. 2014. Mass spectrometry- based electric nose system for assessing rice quality during storage at different temperatures. J Stored Prod Res, 59: 204-208. |

| [89] | Taghinezhad E, Khoshtaghaza M H, Minaei S, Suzuki T, Brenner T. 2016. Relationship between degree of starch gelatinization and quality attributes of parboiled rice during steaming. Rice Sci, 23(6): 339-344. |

| [90] | Tananuwong K, Malila Y. 2011. Changes in physicochemical properties of organic hulled rice during storage under different conditions. Food Chem, 125(1): 179-185. |

| [91] | Tefera T, Kanampiu F de Groote H, Hellin J, Mugo S, Kimenju S, Beyene Y, Boddupalli P M, Shiferaw B, Banziger M. 2011. The metal silo: An effective grain storage technology for reducing post-harvest insect and pathogen losses in maize while improving smallholder farmers’ food security in developing countries. Crop Prot, 30(3): 240-245. |

| [92] | Teles Junior C G S, Vilela M O. 2020. Computer program for determining the equilibrium moisture content of agricultural products. Braz J Biosyst Eng, 14(1): 1-7. |

| [93] | Thomas R, Bhat R, Kuang Y T. 2015. Composition of amino acids, fatty acids, minerals and dietary fiber in some of the local and import rice varieties of Malaysia. Int Food Res J, 22(3): 1148-1155. |

| [94] | Venkatachalapathy N, Udhayakumar R. 2013. Effects of continuous steaming on milling characteristics of two indica rice varieties. Rice Sci, 20(4): 309-312. |

| [95] | Villanova F A, Vanier N L, de Avila Madruga N, Pesek J, Matyska-Pesek M, Elias M C, de Oliveira M. 2017. Improvement of the quality of parboiled rice by using anti-browning agents during parboiling process. Food Chem, 235(5): 51-57. |

| [96] | Wang H, Zhu S M, Ramaswamy H S, Hu F F, Yu Y. 2018. Effect of high pressure processing on rancidity of brown rice during storage. LWT, 93: 405-411. |

| [97] | Wang S J, Copeland L. 2013. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct, 4(11): 1564-1580. |

| [98] | Wang T X, Khir R, Pan Z L, Yuan Q P. 2017. Simultaneous rough rice drying and rice bran stabilization using infrared radiation heating. LWT, 78: 281-288. |

| [99] | Wiset L, Srzednicki G, Wootton M, Driscoll R H, Blakeney A B. 2005. Effects of high-temperature drying on physicochemical properties of various cultivars of rice. Drying Technol, 23: 2227-2237. |

| [100] | Yamamoto S, Kato K. 1999. A basic study on moisture movement and prevention of uneven moisture distribution in grain silo: Possibility of dew condensation to the silo in wall. J Soc Agric Struct, 30: 257-265. |

| [101] | Zeng Y, Jia F G, Meng X Y, Han Y L, Xiao Y W. 2018. The effects of friction characteristic of particle on milling process in a horizontal rice mill. Adv Powder Technol, 29(5): 1280-1291. |

| [102] | Zhang S B, Zhai H C, Huang S X, Cai J P. 2014. A site-directed CO2 detection method for monitoring the spoilage of stored grains by insects and fungi in Chinese horizontal warehouses. J Stored Prod Res, 59: 146-151. |

| [103] | Zhong L J, Cheng F M, Wen X, Sun Z X, Zhang G P. 2005. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars. J Agron Crop Sci, 191(3): 218-225. |

| [104] | Zhou Z K, Robards K, Helliwell S, Blanchard C. 2010. Effect of storage temperature on rice thermal properties. Food Res Int, 43(3): 709-715. |

| [105] | Ziegler V, Ferreira C D, Tonieto L, da Silva J G, de Oliveira M, Elias C. 2017. Storage temperature effects of brown, black and red pericarp brown rice grains on the physicochemical and paste properties. Braz J Food Technol, 20: e2016051. |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||