Rice Science ›› 2017, Vol. 24 ›› Issue (4): 235-240.DOI: 10.1016/j.rsci.2017.04.003

• Orginal Article • Previous Articles

D. Arefieva Olga1( ), A. Zemnukhova Liudmila1,2, A. Kovshun Anastasia1, V. Kovekhova Anna1

), A. Zemnukhova Liudmila1,2, A. Kovshun Anastasia1, V. Kovekhova Anna1

Received:2016-08-20

Accepted:2017-04-21

Online:2017-07-10

Published:2017-04-28

D. Arefieva Olga, A. Zemnukhova Liudmila, A. Kovshun Anastasia, V. Kovekhova Anna. Processing Methods of Alkaline Hydrolysate from Rice Husk[J]. Rice Science, 2017, 24(4): 235-240.

Add to citation manager EndNote|Ris|BibTeX

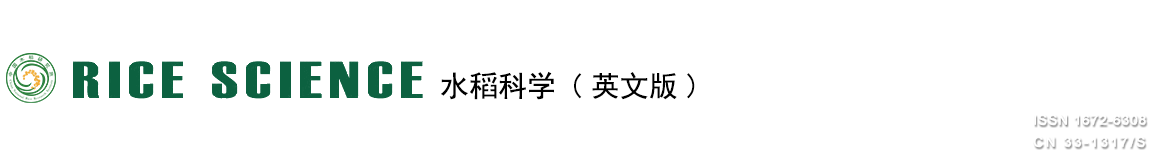

Fig. 1. Schemes of comprehensive processing of alkaline hydrolysate.Scheme I, Processing with further electrochemical treatments of waste water; Scheme II, Processing with alkaline extraction of polysaccharides (PS); Scheme III, Processing with water extraction of polysaccharides and lignin polysaccharides residue; Scheme IV, Processing with lignin polysaccharides residue by vaporization; Scheme V, Processing with alkaline lignin preparation.S1, Alkaline hydrolysate; S2, Silica-free solution.

| Solution processing scheme | pH | Color | Turbidity (mg/L) | COD (mg/L) | BOD5 (mg/L) | Polyphenol (mg/L) | |

|---|---|---|---|---|---|---|---|

| S1 | 13.9 | 95 000 | 3 205 | 50 804 | 34 317 | 1 833 | |

| S2 | 5.9 | 13 833 | 769 | 17 096 | 5 673 | 1 094 | |

| Scheme I | 5.8 | 10 | 7 | 847 | 71 | < 0.025 | |

| Scheme II | 6.6 | 2 | 2 | 126 | - | - | |

| Scheme III | 4.6 | 5 | 1 | 130 | - | - | |

| Scheme V (S3) | 2.4 | 2 346 | 132 | 12 800 | 6 421 | 750 | |

Table 1 Quality parameters of waste water upon processing of rice husk alkaline hydrolysate by various schemes.

| Solution processing scheme | pH | Color | Turbidity (mg/L) | COD (mg/L) | BOD5 (mg/L) | Polyphenol (mg/L) | |

|---|---|---|---|---|---|---|---|

| S1 | 13.9 | 95 000 | 3 205 | 50 804 | 34 317 | 1 833 | |

| S2 | 5.9 | 13 833 | 769 | 17 096 | 5 673 | 1 094 | |

| Scheme I | 5.8 | 10 | 7 | 847 | 71 | < 0.025 | |

| Scheme II | 6.6 | 2 | 2 | 126 | - | - | |

| Scheme III | 4.6 | 5 | 1 | 130 | - | - | |

| Scheme V (S3) | 2.4 | 2 346 | 132 | 12 800 | 6 421 | 750 | |

| Waste water quality indicator | Alkaline hydrolysate of rice husk | Black liquor of wheat straw | Black liquor of rice straw | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (In this work) | (Sulphate pulping) a | (Sodium hydroxide pulping) b | |||||||||

| Before treatment | After treatment | Before treatment | After treatment | Before treatment | After treatment | ||||||

| Color (Degree) | 13 833 | 10 | 1 750 | 175 | Brown | - | |||||

| BOD5 (mgO2/L) | 5 673 | - | 615-670 | 50 | 300-400 | - | |||||

| COD (mgO/L) | 17 096 | 847 | 2 000-2 100 | 410 | 5 000-6 000 | 160 | |||||

| Conditions of electrochemical treatment | |||||||||||

| Material of the electrodes (cathode and anode) | Anode: Ruthenium oxide-titanium; | Anode-Cathode: Iron | Anode: lead sheets (PbO2); | ||||||||

| Cathode: Commercial titanium (Brand ВТ1-0) | (Magnetite Fe3O4) | Cathode: stainless steel | |||||||||

| Current density (mA/cm2) | 100 | 5, 6 | 6, 6 | ||||||||

| Electrolysis time (min) | 90 | 90 | 60 | ||||||||

| Volume of the cell (mL) | 50 | 2 000 | - | ||||||||

| NaCl concentration (g/L) | 4 c | 0.625 d | 1 b | ||||||||

Table 2 Comparative analysis of electrochemical treatment of alkaline hydrolysate obtained from non-wood plant raw material.

| Waste water quality indicator | Alkaline hydrolysate of rice husk | Black liquor of wheat straw | Black liquor of rice straw | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (In this work) | (Sulphate pulping) a | (Sodium hydroxide pulping) b | |||||||||

| Before treatment | After treatment | Before treatment | After treatment | Before treatment | After treatment | ||||||

| Color (Degree) | 13 833 | 10 | 1 750 | 175 | Brown | - | |||||

| BOD5 (mgO2/L) | 5 673 | - | 615-670 | 50 | 300-400 | - | |||||

| COD (mgO/L) | 17 096 | 847 | 2 000-2 100 | 410 | 5 000-6 000 | 160 | |||||

| Conditions of electrochemical treatment | |||||||||||

| Material of the electrodes (cathode and anode) | Anode: Ruthenium oxide-titanium; | Anode-Cathode: Iron | Anode: lead sheets (PbO2); | ||||||||

| Cathode: Commercial titanium (Brand ВТ1-0) | (Magnetite Fe3O4) | Cathode: stainless steel | |||||||||

| Current density (mA/cm2) | 100 | 5, 6 | 6, 6 | ||||||||

| Electrolysis time (min) | 90 | 90 | 60 | ||||||||

| Volume of the cell (mL) | 50 | 2 000 | - | ||||||||

| NaCl concentration (g/L) | 4 c | 0.625 d | 1 b | ||||||||

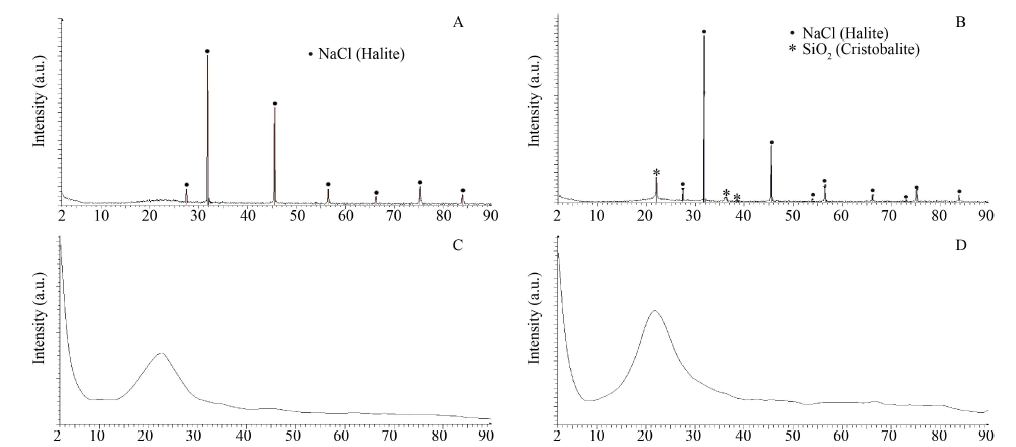

| Sample | Product | Color | Yield (%) | SiO2 (%) | Ssp (m2/g) | x-ray phase analysis |

|---|---|---|---|---|---|---|

| No. 1 | Crude | Brown | 50 | 36 | 5.9 | AP + NaCl |

| No. 2 | Burnt at 650 ºC | Black | 29 | 60 | 5.6 | AP + NaCl + Cristobalite |

| No. 3 | Washed and air-dried | Beige | 19 | 96 | 59.2 | AP |

| No. 4 | Washed and burnt at 650 ºC | White | 9 | 99 | 35.8 | AP |

Table 3 Description of silicium dioxide samples obtained from rice husk alkaline hydrolysate.

| Sample | Product | Color | Yield (%) | SiO2 (%) | Ssp (m2/g) | x-ray phase analysis |

|---|---|---|---|---|---|---|

| No. 1 | Crude | Brown | 50 | 36 | 5.9 | AP + NaCl |

| No. 2 | Burnt at 650 ºC | Black | 29 | 60 | 5.6 | AP + NaCl + Cristobalite |

| No. 3 | Washed and air-dried | Beige | 19 | 96 | 59.2 | AP |

| No. 4 | Washed and burnt at 650 ºC | White | 9 | 99 | 35.8 | AP |

Fig. 2. x-ray diffraction patterns of silica dioxide. A, Crude (No. 1); B, Burnt (No. 2); C, Washed and air-dried (No. 3); D, Washed and burnt at 650 ºC (No. 4).

| 1 | Arefieva O D, Zemnukhova L A, Morgun N P, Rybin V G, Tsvetnov M A, Kovshun A A, Panasenko A E.2015. Removal of (2,4-dichlorophenoxy) acetic acid from aqueous solutions using low-cost sorbents.Air Soil Water Res, 8: 59-65. |

| 2 | Cai X, Hong R Y, Wang L S, Wang X Y, Li H Z, Zheng Y, Wei D G.2009. Synthesis of silica powders by pressured carbonation.Chem Eng J, 151: 380-386. |

| 3 | Chang C N, Ma Y S, Fang G C, Chao A C, Tsai M C, Sung H F.2004. Decolorizing of lignin wastewater using the photochemical UV/TiO2 process.Chemosphere, 56(10): 1011-1017. |

| 4 | Clescerl L S.1998. Standard Methods for the Examination of Water and Wastewater. 20th Edition. Washington, USA: American Public Health Association: 988-992. |

| 5 | Comninellis C.1994. Electrochemical oxidation of organic pollutants for wastewater treatment.Stud Envi Sci, 59: 77-102. |

| 6 | Deineko I P.2012. Disposal of lignins: Achievements, problems and prospects.Chem Plant Mater, 1: 5-20. |

| 7 | Directive document 52.24.420-2005.2005. Biochemical Oxygen Demand in the Waters: Methodology for Defining by Bottle Method. the Russia Federation. |

| 8 | El-Ashtoukhy E S Z, Amin N K, Abdelwaha O.2009. Treatment of paper mill effluents in a batch-stirred electrochemical tank reactor.Chem Eng J, 146(2): 205-210. |

| 9 | Gnedenkov S V, Opra D P, Zemnukhova L A, Sinebrukhov S L, Minaev A N, Kedrinskiy I A, Sergienko V I.2015. Electrochemical performance of Klason lignin as the positive electrode material for lithium-current source.Chem Plant Mater, 2: 239-248. |

| 10 | Issa R M, Abou-Sekkina M M, Bastawisy A M, Khedr A M, El-Helece W A.2011. New treatment of the black liquor produced from pulping of rice straw.Elixir Chem Phys, 33: 2276-2278. |

| 11 | Kholomeidik A N, Nikolenko Y M, Zemnukhova L A, Ustinov A Y, Mayorov V Y, Polyakova N V.2015. Study of rice husk silica adsorption with the respect to copper ions(II) and manganese(II).Chem Plant Mater, 3: 169-176. |

| 12 | Lafi W K.2011. Electro-coagulation treatment of wastewater from paper industry. In: Recent Researches in Energy, Environment, Devices, Systems, Communications and Computers. International Conference on Energy, Environment, Devices, Systems, Communications, Computers. Venice, Italy: 61-69. |

| 13 | Lora J H, Glasser W G.2002. Resent industrial application of lignin: A sustainable alternative to nonrenewable materials.J Polym Environ, 10(1/2): 39-48. |

| 14 | Mahesh S, Prasad B, Mall I D, Mishra I M.2006. Electrochemical degradation of pulp and paper mill wastewater: Part 1. COD and color removal.Ind Eng Chem Res, 45(8): 2830-2839. |

| 15 | Mamontova V A, Tomshich S V, Komandrova N A, Zemnukhova L A.2005. Polysaccharides from rice production waste. In: Proceedings of the III International Conference. Minsk, the Republic of Belarus. |

| 16 | Minu K, Jiby K K, Kishore V V N.2012. Isolation and purification of lignin and silica from the black liquor generated during the production of bioethanol from rice straw.Biomass Bioenerg, 39: 210-217. |

| 17 | Olsson J.2013. Separation of lignin and hemicelluloses from black liquor and pre-treated black liquor by nanofiltration.Dep Chem Eng, 2: 1-6. |

| 18 | Patel U D, Suresh S.2008. Electrochemical treatment of pentachlorophenol in water and pulp bleaching effluent.Sep Pur Technol, 61(2): 115-122. |

| 19 | Perng Y S, Wang I C, Yu S T, Lin Y F.2008. Application of an electro-oxidation treatment method to industrial paper mill effluents in the lab.Taiwan J Forest Sci, 23(2): 111-123. |

| 20 | Pijiarn N, Jaroenworaluck A, Sunsaneeyametha W, Stevens R.2010. Synthesis and characterization of nanosized-silica gels formed under controlled conditions.Powder Technol, 203(3): 462-468. |

| 21 | Ugurlu M, Gurses A, Dogar C, YalcIn M.2008. The removal of lignin and phenol from paper mill effluents by electrocoagulation.J Environ Manag, 87(3): 420-428. |

| 22 | Vurasko А V, Driker B N, Zemnukhova L А, Galimova А R.2007. Resource-saving technology for producing pulp at complex processing of rice straw.Chem Plant Mater, 2: 21-25. |

| 23 | Wang B, Chang X, Ma H Z.2008. Electrochemical oxidation of refractory organics in the coking wastewater and chemical oxygen demand (COD) removal under extremely mild conditions.Ind Engin Chem Res, 47(21): 8478-8483. |

| 24 | Zaieda M, Bellakhal N.2009. Electrocoagulation treatment of black liquor from paper industry.J Hazard Mater, 163: 995-1000. |

| 25 | Zayas T, Picazo M, Salgado L.2011. Removal of organic matter from paper mill effluent by electrochemical oxidation.J Water Res Prot, 3(1): 32-40. |

| 26 | Zemnukhova L A, Arefieva O D, Kovshun A A.2013. Treatment of alkaline waste water generated by the hydrolysis of rice husk.Adv Mater Res, 781/784: 2087-2090. |

| 27 | Zemnukhova L A, Tomshich S V, Mamontova V A, Komandrova N A, Fedorischeva G A, Sergiyenko V I.2004. Study of structure and properties of rice husk polysaccharides.J Appl Chem, 77(11): 1901-1904. |

| 28 | Zemnukhova L A, Chernov B B, Schetinina G P, Kharchenko U V, Fedorischeva G A.2006. Method for Steel Protection From Corrosion. The Russian Federation, Patent 2289639. |

| 29 | Zemnukhova L A, Fedorischeva G A.2010. Method for Obtaining Silica Dioxide. The Russian Federation, Patent 2394764. |

| 30 | Zemnukhova L A, Panasenko A E, Tsoi E A, Fedorischeva G A, Shapkin N P, Artemyanov A P, Maiorov V Y.2014. Composition and structure of amorphous silica produced from rice husk and straw.Inorg Mater, 50(1): 75-81. |

| 31 | Zhang X J, Zhao Z H, Ran G J, Liu Y, Liu S, Zhou B, Wang Z.2013. Synthesis of lignin-modified silica nanoparticles from black liquor of rice straw pulping.Powder Technol, 246: 664-668. |

| [1] | Prathap V, Suresh KUMAR, Nand Lal MEENA, Chirag MAHESHWARI, Monika DALAL, Aruna TYAGI. Phosphorus Starvation Tolerance in Rice Through a Combined Physiological, Biochemical and Proteome Analysis [J]. Rice Science, 2023, 30(6): 8-. |

| [2] | Serena REGGI, Elisabetta ONELLI, Alessandra MOSCATELLI, Nadia STROPPA, Matteo Dell’ANNO, Kiril PERFANOV, Luciana ROSSI. Seed-Specific Expression of Apolipoprotein A-IMilano Dimer in Rice Engineered Lines [J]. Rice Science, 2023, 30(6): 6-. |

| [3] | Sundus ZAFAR, XU Jianlong. Recent Advances to Enhance Nutritional Quality of Rice [J]. Rice Science, 2023, 30(6): 4-. |

| [4] | Kankunlanach KHAMPUANG, Nanthana CHAIWONG, Atilla YAZICI, Baris DEMIRER, Ismail CAKMAK, Chanakan PROM-U-THAI. Effect of Sulfur Fertilization on Productivity and Grain Zinc Yield of Rice Grown under Low and Adequate Soil Zinc Applications [J]. Rice Science, 2023, 30(6): 9-. |

| [5] | FAN Fengfeng, CAI Meng, LUO Xiong, LIU Manman, YUAN Huanran, CHENG Mingxing, Ayaz AHMAD, LI Nengwu, LI Shaoqing. Novel QTLs from Wild Rice Oryza longistaminata Confer Rice Strong Tolerance to High Temperature at Seedling Stage [J]. Rice Science, 2023, 30(6): 14-. |

| [6] | LIN Shaodan, YAO Yue, LI Jiayi, LI Xiaobin, MA Jie, WENG Haiyong, CHENG Zuxin, YE Dapeng. Application of UAV-Based Imaging and Deep Learning in Assessment of Rice Blast Resistance [J]. Rice Science, 2023, 30(6): 10-. |

| [7] | Md. Forshed DEWAN, Md. AHIDUZZAMAN, Md. Nahidul ISLAM, Habibul Bari SHOZIB. Potential Benefits of Bioactive Compounds of Traditional Rice Grown in South and South-East Asia: A Review [J]. Rice Science, 2023, 30(6): 5-. |

| [8] | Raja CHAKRABORTY, Pratap KALITA, Saikat SEN. Phenolic Profile, Antioxidant, Antihyperlipidemic and Cardiac Risk Preventive Effect of Chakhao Poireiton (A Pigmented Black Rice) in High-Fat High-Sugar induced Rats [J]. Rice Science, 2023, 30(6): 11-. |

| [9] | LI Qianlong, FENG Qi, WANG Heqin, KANG Yunhai, ZHANG Conghe, DU Ming, ZHANG Yunhu, WANG Hui, CHEN Jinjie, HAN Bin, FANG Yu, WANG Ahong. Genome-Wide Dissection of Quan 9311A Breeding Process and Application Advantages [J]. Rice Science, 2023, 30(6): 7-. |

| [10] | JI Dongling, XIAO Wenhui, SUN Zhiwei, LIU Lijun, GU Junfei, ZHANG Hao, Tom Matthew HARRISON, LIU Ke, WANG Zhiqin, WANG Weilu, YANG Jianchang. Translocation and Distribution of Carbon-Nitrogen in Relation to Rice Yield and Grain Quality as Affected by High Temperature at Early Panicle Initiation Stage [J]. Rice Science, 2023, 30(6): 12-. |

| [11] | Nazaratul Ashifa Abdullah Salim, Norlida Mat Daud, Julieta Griboff, Abdul Rahim Harun. Elemental Assessments in Paddy Soil for Geographical Traceability of Rice from Peninsular Malaysia [J]. Rice Science, 2023, 30(5): 486-498. |

| [12] | Monica Ruffini Castiglione, Stefania Bottega, Carlo Sorce, Carmelina SpanÒ. Effects of Zinc Oxide Particles with Different Sizes on Root Development in Oryza sativa [J]. Rice Science, 2023, 30(5): 449-458. |

| [13] | Tan Jingyi, Zhang Xiaobo, Shang Huihui, Li Panpan, Wang Zhonghao, Liao Xinwei, Xu Xia, Yang Shihua, Gong Junyi, Wu Jianli. ORYZA SATIVA SPOTTED-LEAF 41 (OsSPL41) Negatively Regulates Plant Immunity in Rice [J]. Rice Science, 2023, 30(5): 426-436. |

| [14] | Ammara Latif, Sun Ying, Pu Cuixia, Noman Ali. Rice Curled Its Leaves Either Adaxially or Abaxially to Combat Drought Stress [J]. Rice Science, 2023, 30(5): 405-416. |

| [15] | Liu Qiao, Qiu Linlin, Hua Yangguang, Li Jing, Pang Bo, Zhai Yufeng, Wang Dekai. LHD3 Encoding a J-Domain Protein Controls Heading Date in Rice [J]. Rice Science, 2023, 30(5): 437-448. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||